I didn’t get that much work done on the airplane last week so it feels great to get back in the saddle.

During the prior week I bought a 7.5 inch long rivet set to install some of these rivets around the edges of the angle bracket. A lot of the rivets are close to the edge of this bracket so I went a little overboard with the number of rivets I installed.

I made a batch of sealant and did some last minute inspecting and sealing of the interior of the right tank. During this time I also sealed the rivets I set on the bracket.

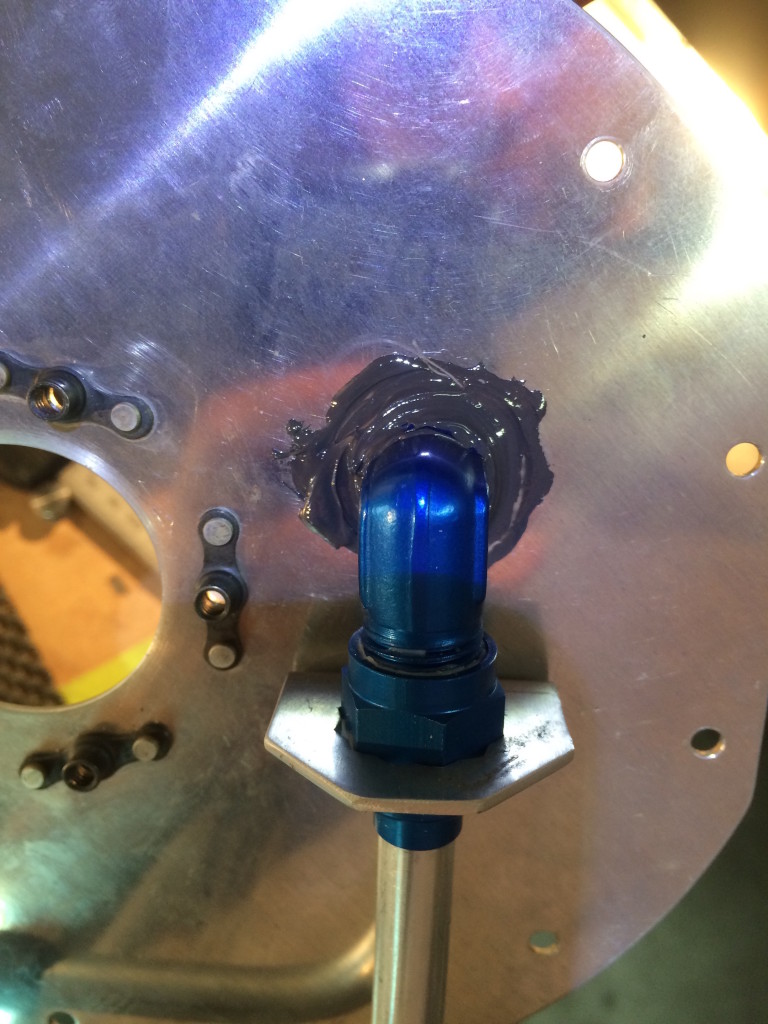

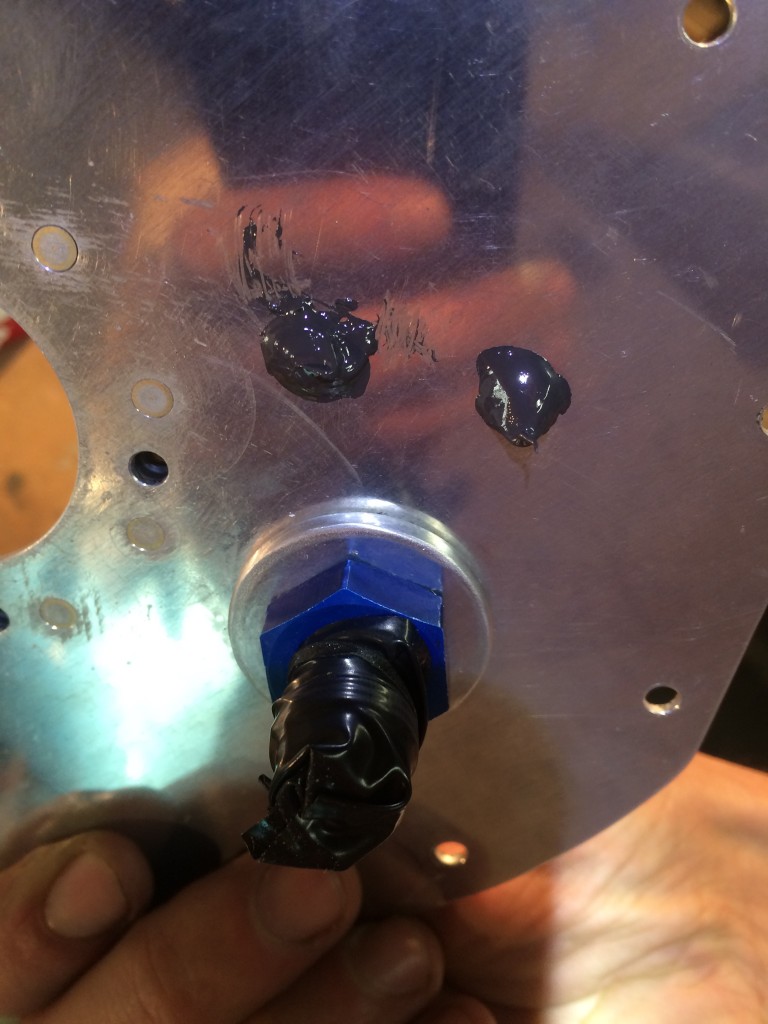

I sealed the fuel fitting and blind rivets on the access panel.

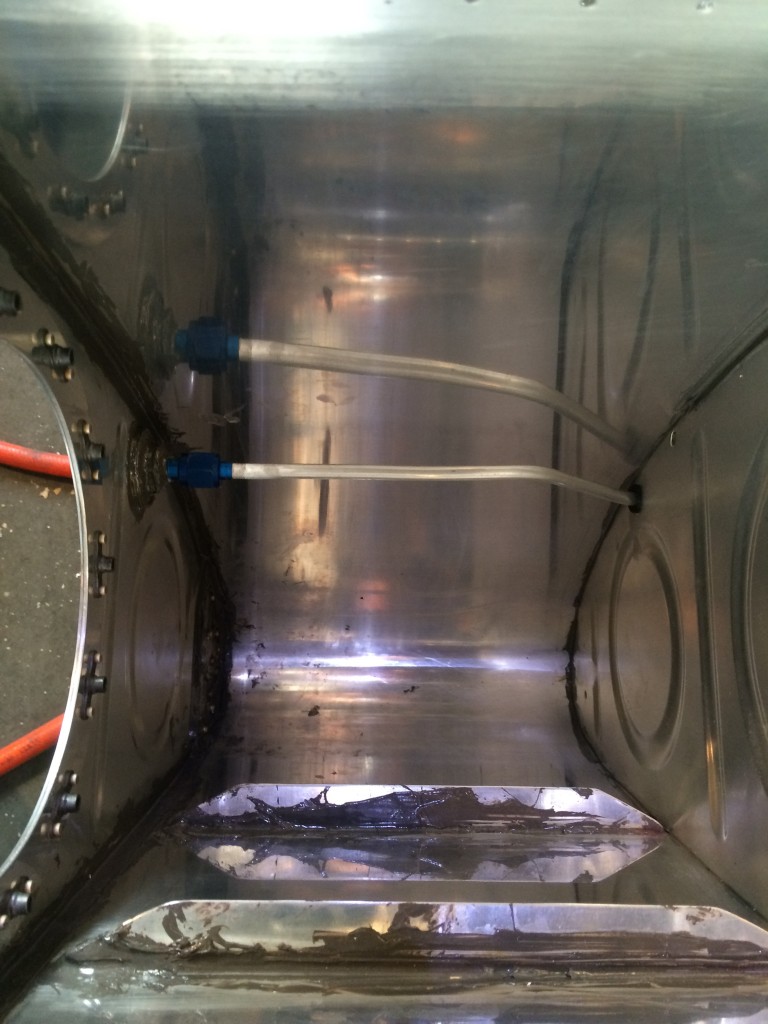

The next task on the right tank was the installation of the vent tube. Van’s supplies the aluminum tubing in just a big roll, which has to be straightened out. I cut a generous length of material and just used a flat table to roll it out.

It took my a little time to figure out how to get a good flare using my flaring tool. The contraption is a little janky, but it gets the job done. The spec says the OD of the flare should be .340-.360 inches.

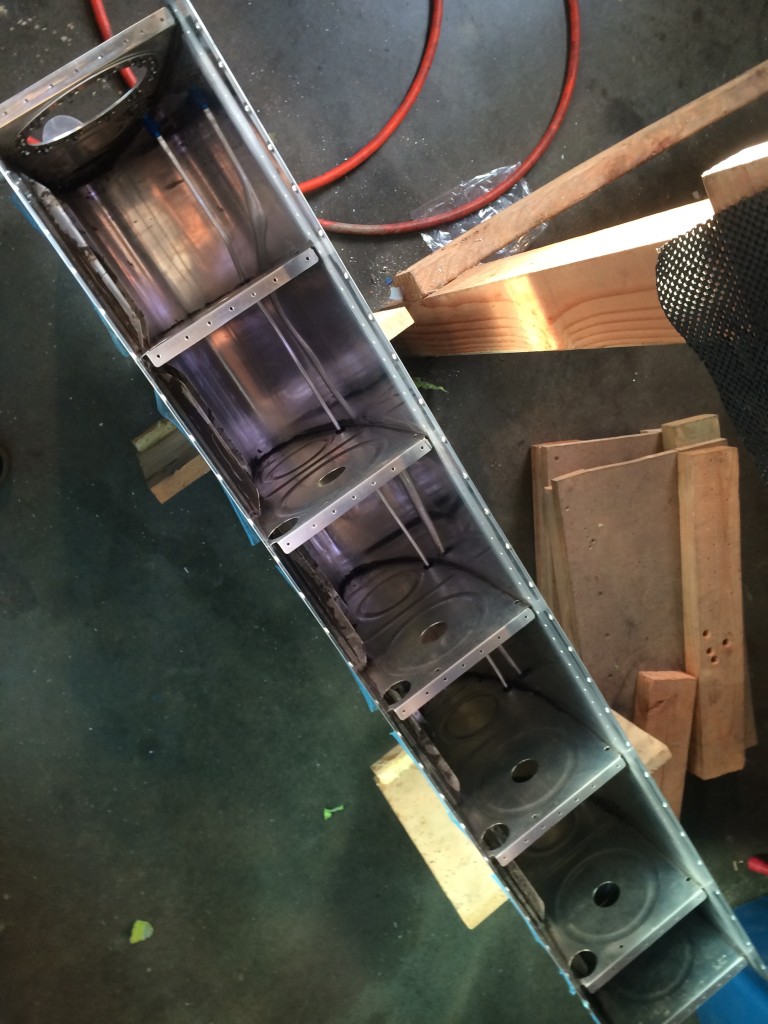

Getting the vent tube installed in the tank was a pretty big hassle because the inboard rib was already installed. Routing the tube was not a straight-shot through the ribs so it had to be bent and straightened as it was routed through the tank. It was also challenging to figure out how long the tube should actually be in the installed state. It took three attempts to install the tube before I was satisfied with the length. I has to partially back it out of the tank and cut a portion off before reinstalling the tube and checking the length.

In the end the tube came out great.

I got pretty lucky that the jog I put in the tubing didn’t interfere with the rib. The bend is basically right at the rib location.

Here’s the outboard side of the tube. I just used my hand to bend the end of the tube to the highest point in the tank.

I’m basically ready to close this tank out. I just need to do a through inspection and cleaning before installing the baffle.