[<<Prev] [Next>>]

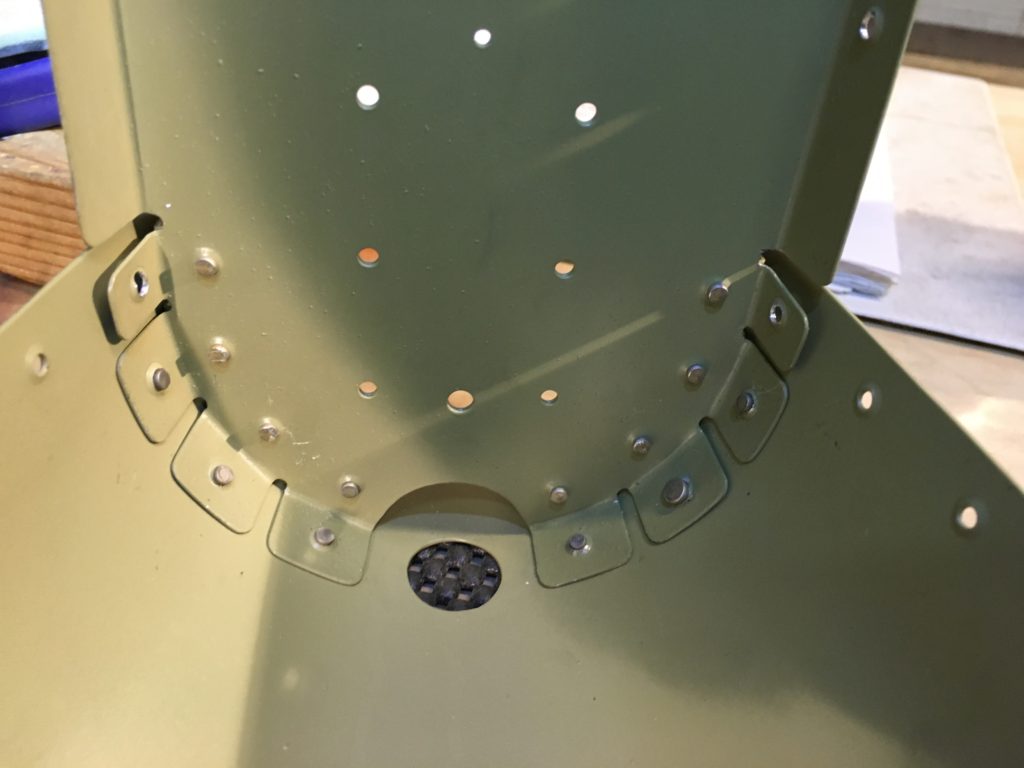

I started riveting the aft-most bulkheads to the bottom skin. Handling these parts was a bit unwieldy, but everything turned out fine. On the F-712 bulkhead, I had to use an Oops rivet due to a bad removal job on a rivet. You can see the larger shop head in the image below.

To get the F-711 bulkhead riveted, I used a C-clamp to fix it to the table. All rivets went in very cleanly.

Here’s the final product. The next session should be super fun.