Today was all about finishing up the center section prep. The first thing I did was locate the scallops that provide clearance for the step weldment. To do this, I clecoed the side skin to the center section structure. This allowed me to use a long #40 drill bit to function as a stand-in for the access of the tube. After I knew where the access was located, I used calipers to mark off where the tube would actually contact the flanges.

Since the tube doesn’t actually have to contact the flanges, I removed .150 more material than required.

Here are the cut flanges. I used my grinding wheel to remove the majority of the material.

I clamped my newly fabricated spacers to the forward F-704 bulkhead could be match drilled.

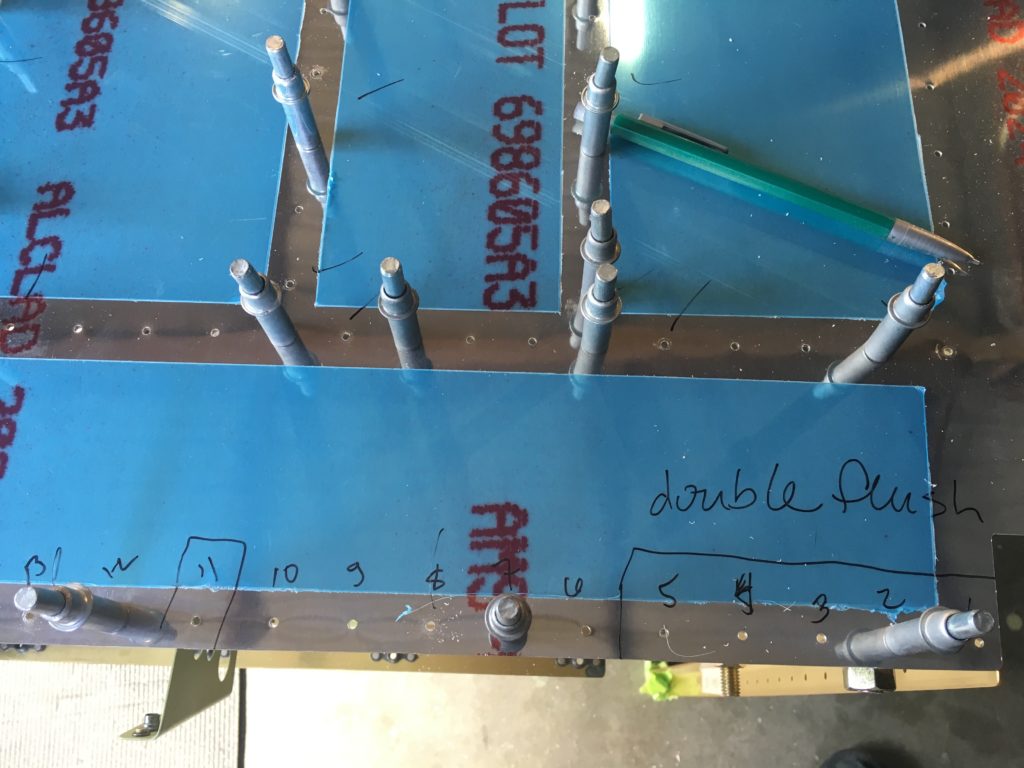

I marked off the holes that will require countersinking. The plans give you the option of countersinking or dimpling the remaining rivets. I’m going to be dimpling the holes because it forms a stronger joint.

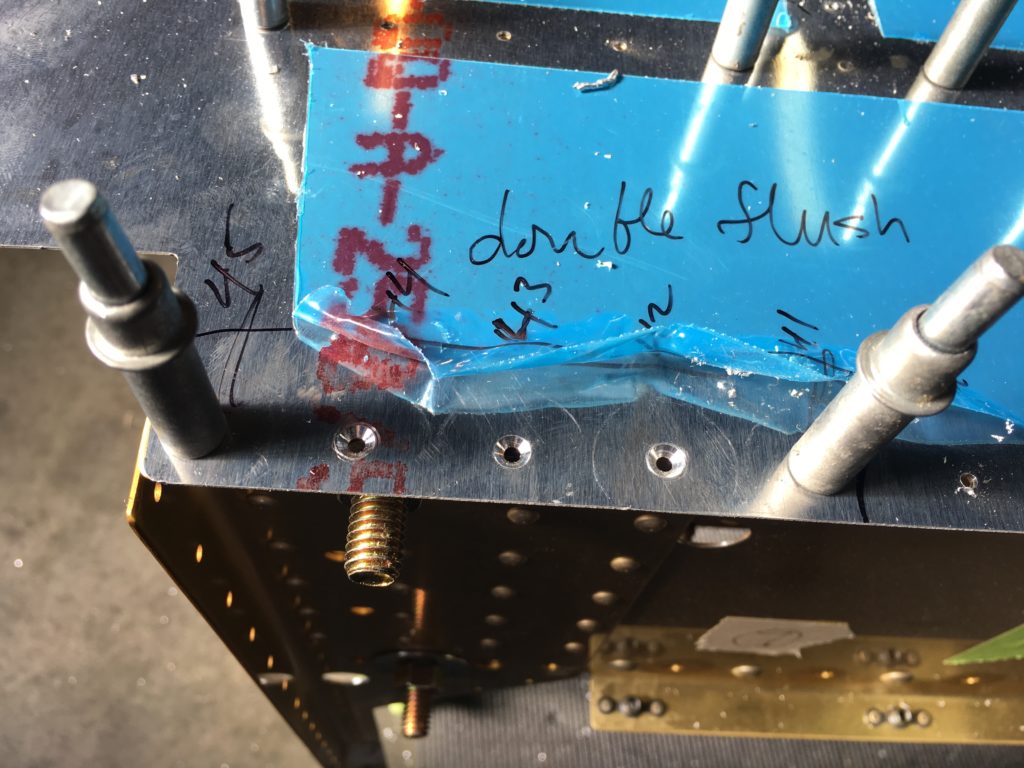

Here are those countersunk holes. I need to figure out what I’m going to do on the opposite side of the flange to form the double flush holes.

My final activity of the day was match drilling the F-704H side walls. Now it’s time to start disassembling everything so the parts can be deburred, dimpled, and primed.

[<<Prev] [Next>>]