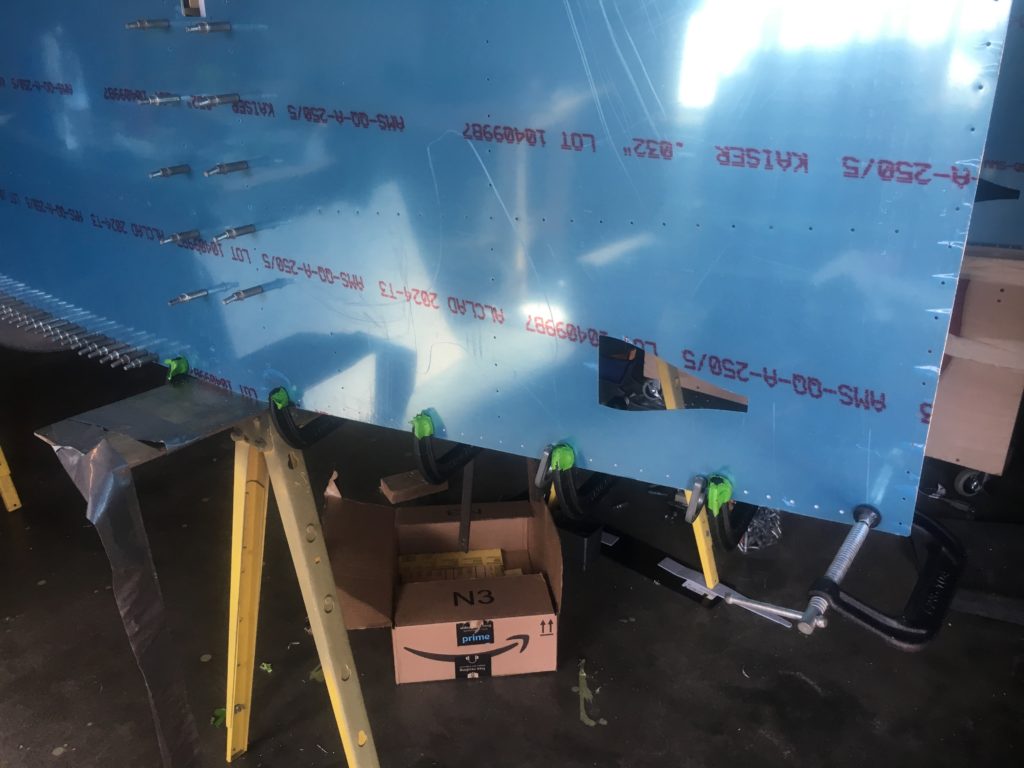

The big task for the day was getting the left longeron drilled. The longeron was located flush with the edge of the skin using a square. I used c-clamps to hold the longeron in place before drilling. I used my egg cup and bushing to drill the holes. I started with a #43 drill size before moving to a #40 reamer. Using 2 drills (my air drill and power drill) for this task was super helpful. As clecos were added, I moved the clamps from aft to forward.

All holes for the left longeron have been drilled aft of the F-704 bulkhead.

Instead of moving to the right longeron, I moved to the next step in the plans and contented working on the left longeron. The longeron was a little long so I cut it back so there’s a .800 gap from the front of the skin to the end of the longeron. Van’s tells you the minimum gap I can be .750, so I increased it by .050. I clamped the longeron to the skin an drilled the holes.

Here’s the product of a long day’s work. 176 holes were drilled on the left longeron. Next time I’ll do the same for the right side!