The first thing I did in the hangar today was get a new overhead light installed. Even though I’ve been in this spot for 5 years, it’s never too late to make improvements. The ladder I got for Christmas is awesome!

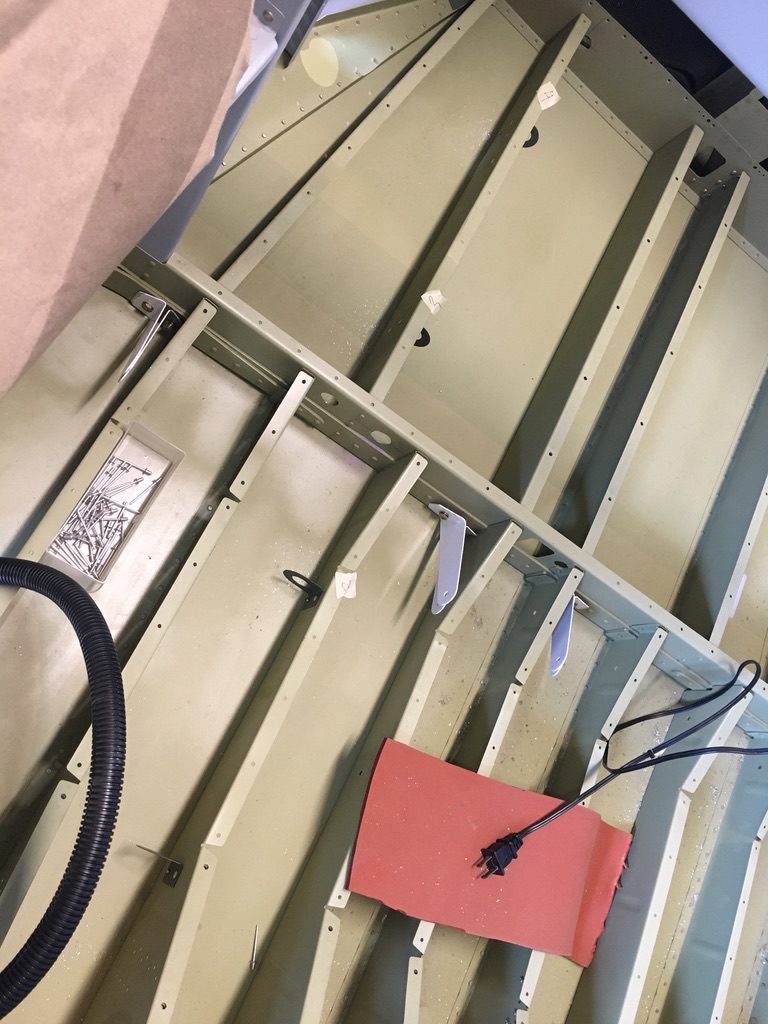

I got the conduit mounting brackets installed on the right side of the airplane. You can see where I accidentally drilled a .75 diameter hole in the incorrect location on the F-705 bulkhead. I had planned on mounting the wiring through that hole, but I forgot the external step tube passes through that area.

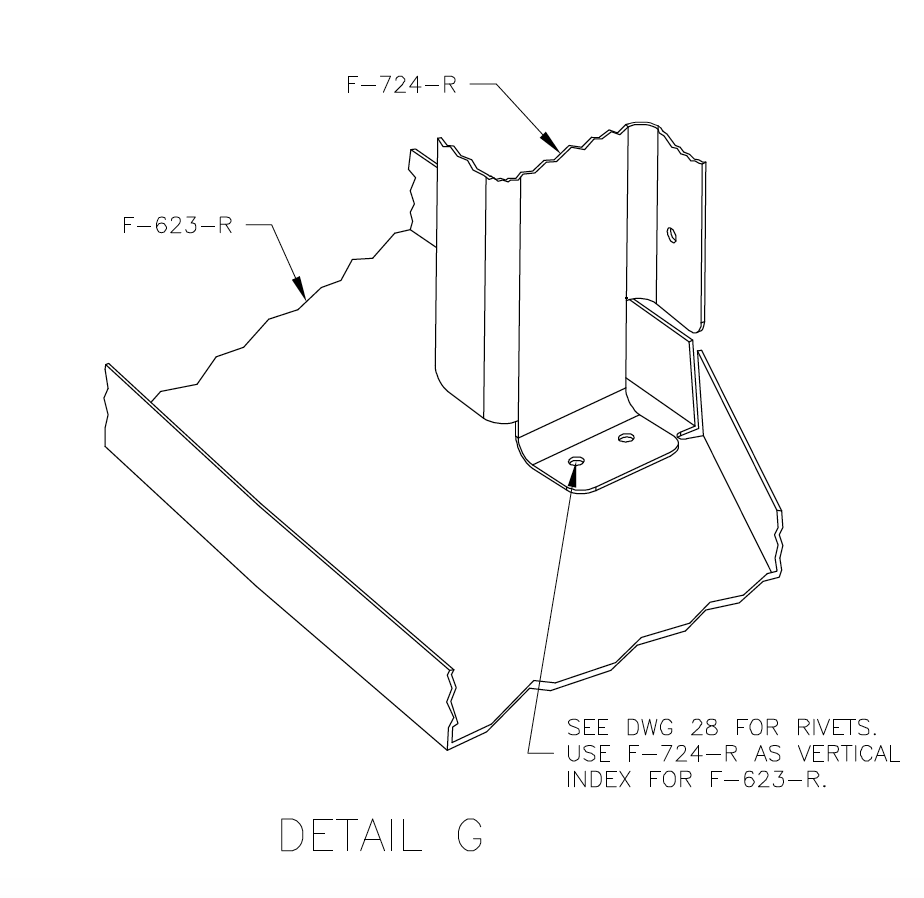

Instead of working on the conduit routing on the left side of the plane, I jumped ahead to a different area of the plane. When I had originally riveted the fuselage, a ~.060 gap was left between the tab ofF-724 and F-623. The picture below was pulled from Drawing 25.

I made 2 spacers from .063 material.

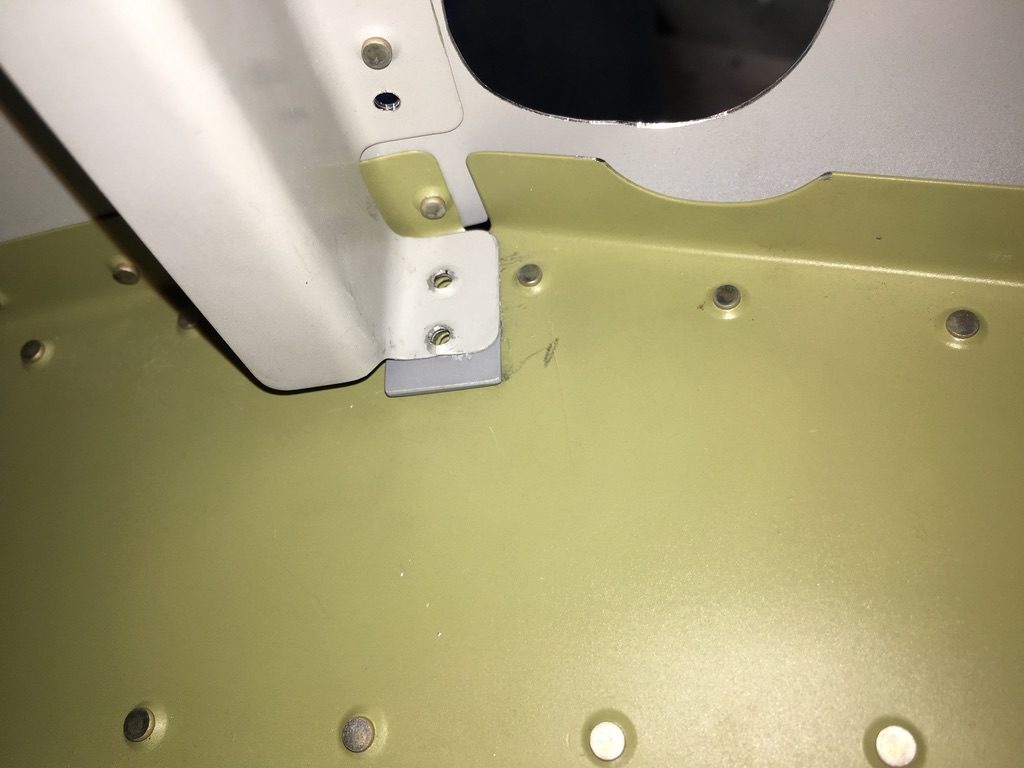

Here’s the spacer being fitted with he fuselage. I tried to flatted the dimpled on the bulkhead using my pop rivet pulled dimple die (the dies were flipped so 2 flat faces were squeezing the aluminum). It’s worked decently well, but the dimpled wasn’t totally flat.

I just used blind rivets to make this work. This isn’t the best picture, but you can see where the rivets are located.