[<<Prev] [Next>>]

I burned a PTO day at work because I’ve been feeling burnt out. I wasn’t expecting to make it to the hangar, but I ended going in and knocking out 2 fuel lines.

Vans supplies coiled 3003-0 aluminum. It’s super easy to work with, but its material properties are terrible (Ftu = 19 ksi). Since the fuel system is obviously critical, I decided to switch all the tubes to 6061-T6 aluminum (Ftu 42 ksi). There’s an added benefit that the stock tubes are supplied straight rather than coiled. This provides a much cleaner appearance. Going with the higher strength tubes made the tube routing more difficult, but I feel great about this decision.

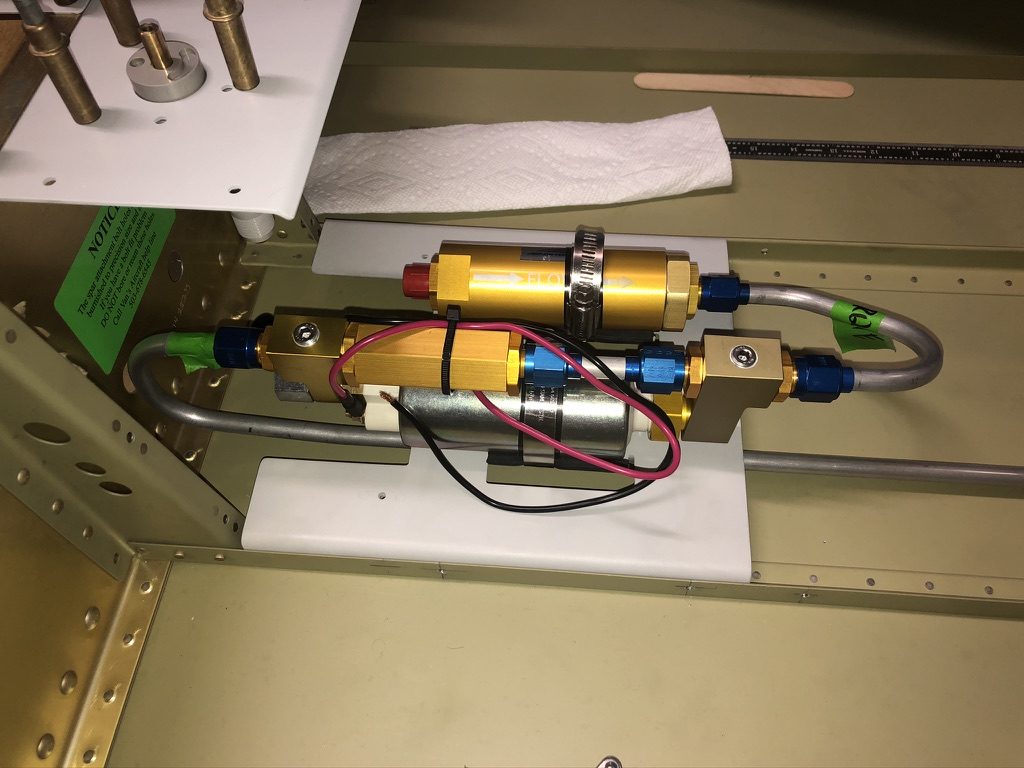

Unlike all the crazy pretzel tubes we make at SpaceX, the RV tubes are fabricated by doing just rough measurements making things on assembly. The first thing I did was route the tube from the filter outlet to the pump inlet (right side of picture). The route of this tube controls the position of the pump on the mounting plate since you can’t have the tube bend interfere with the pump housing.

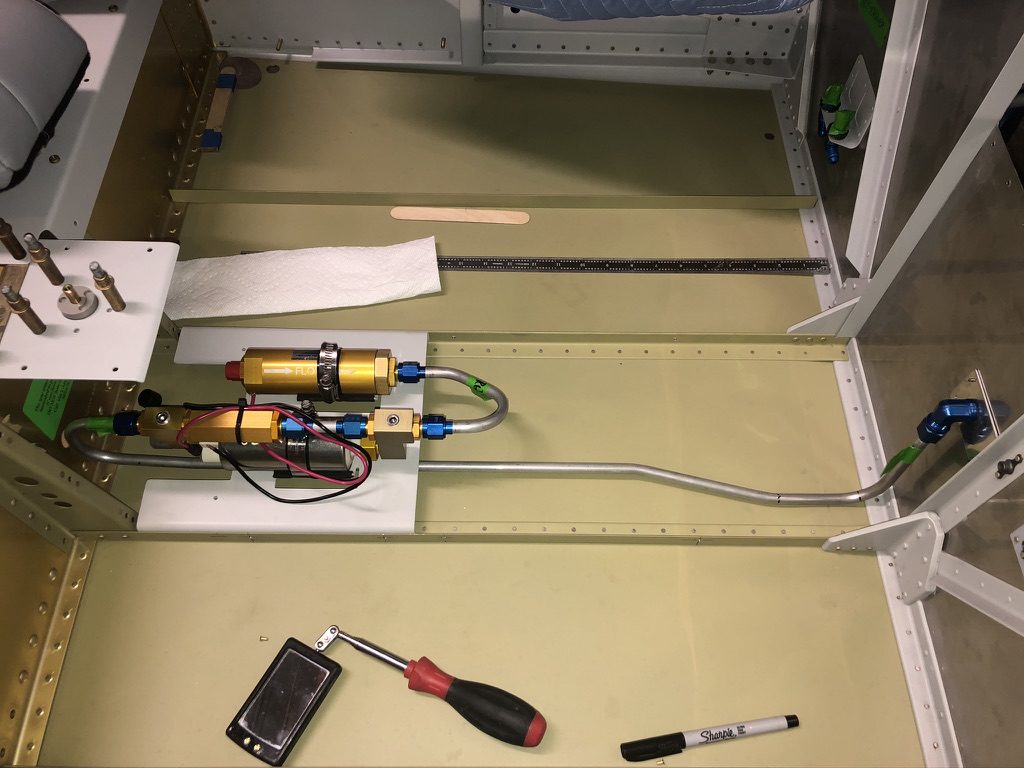

You can see how I routed the main fuel line. Overall, I’m pleased with how it came out.

I tried to route the tube from the fuel selector to the filter. After several attempts and a bunch of scrap tube, I’m convinced with is not possible. I think the bend radius on my bender is too big. I’m just going to use a 90 degree fitting to make this work.

This is the tube bender I used. I had originally purchased a cheap bender off Aircraft Spruce. I’m really glad to move to this heavier duty tool.

[<<Prev] [Next>>]