The day was spent getting the right landing gear mount installed in the airplane. This was a pretty slow process of getting the gear installed, checking the fit, and making correction.

The first thing I did was match drill the single bolt hole that holds the landing gear leg to the mount. I used a .311 reamer to match drill the parts.

It was basically impossible to get the gear to nest in the appropriate location so I drilled out the outboard nutplate. This was the main source of interference.

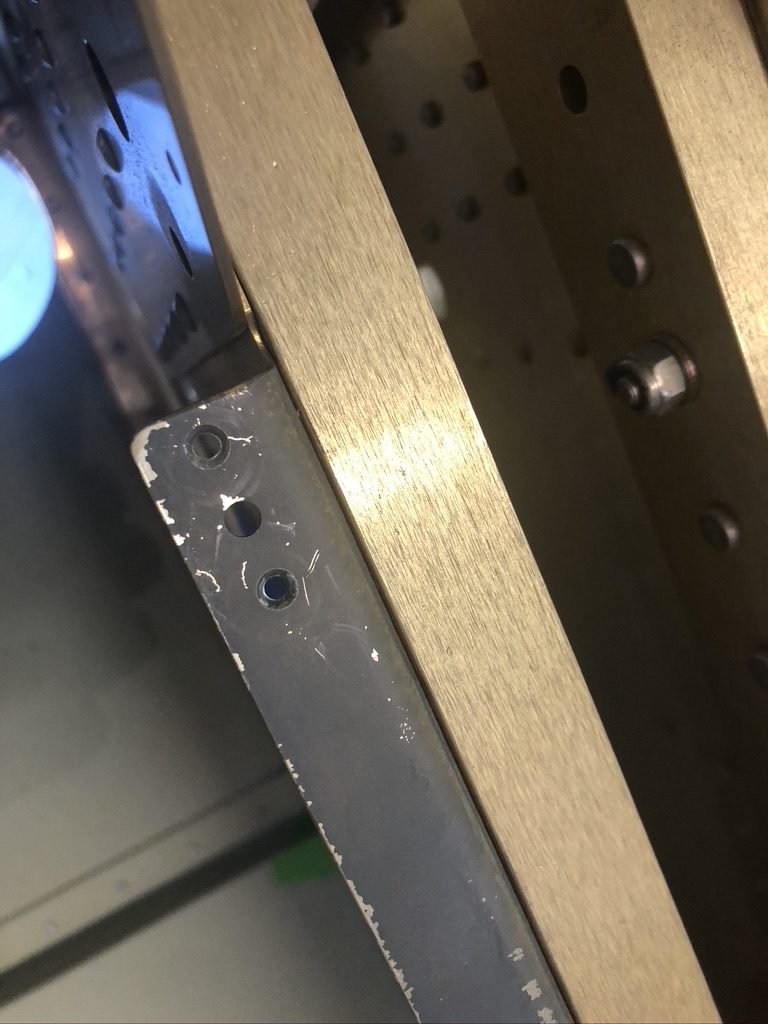

I removed some material on the floor stiffener flange. This picture doesn’t do a great job showing what I did, but I just trimmed back that flange a bit so the gear would fall into that area more easily.

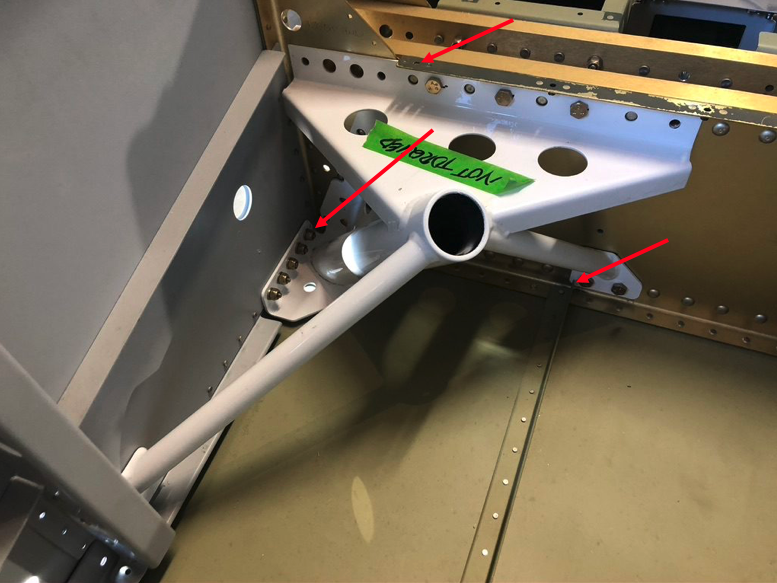

This image shows all the areas I modified. The lower right arrow shows where I had to scallop the gear flange to avoid a rivet on the fuselage. It’s tough to see the modification in the picture, but I basically just carved away the material that was sitting on the shop head of the rivet. The material removal allows those 5 bolts to clamp up flat against the fuselage wall.

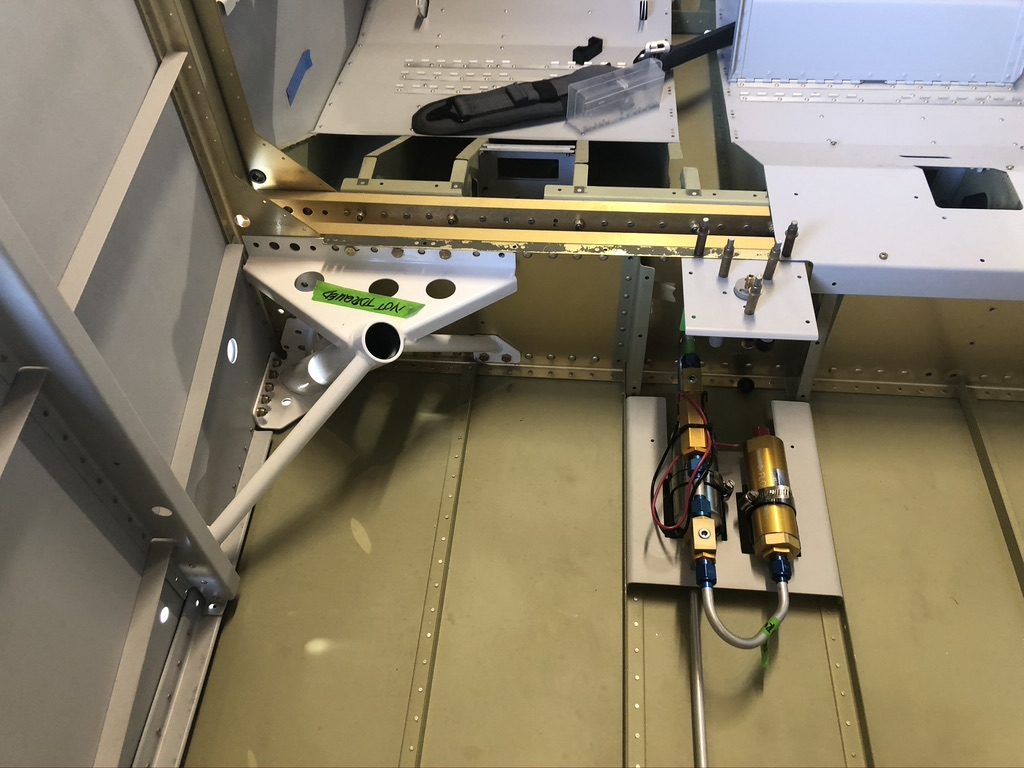

After about 5 iterations of trying to get everything to fit up properly, I finally got the gear to nest properly in the fuselage. The gear really make the interior look badass.

Here’s the gear mount sticking out of the fuselage. Looking good!