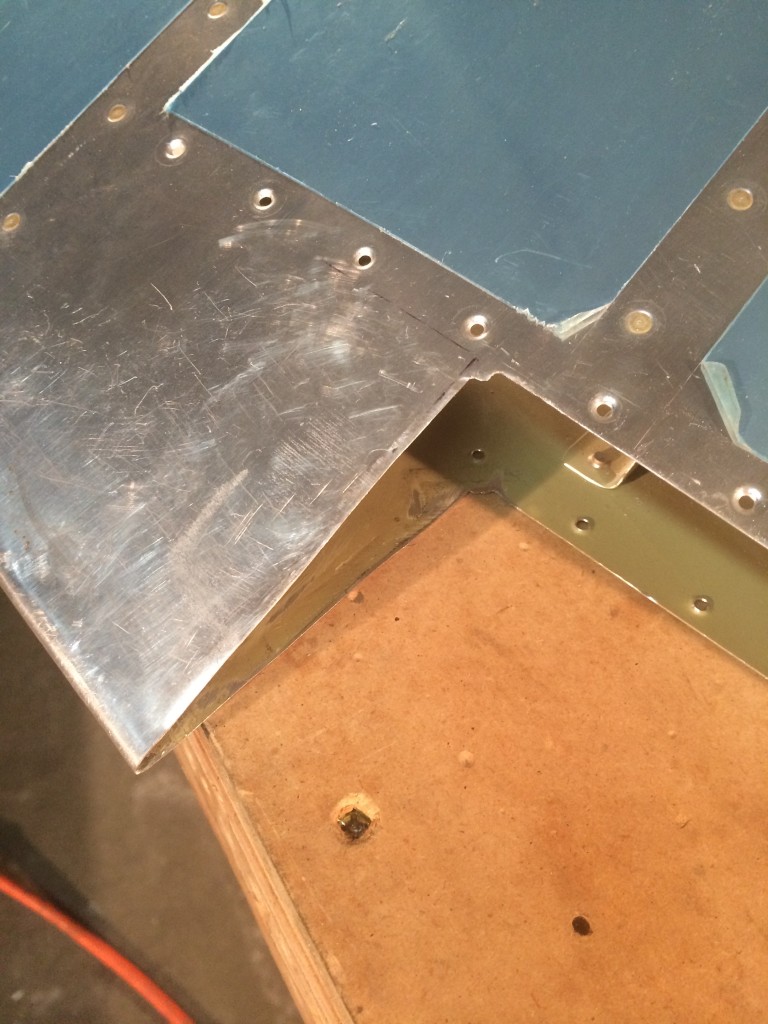

I put in another solid 12 hour day at the hangar. I started by drilling out the reinforcement plates and installing them on the correct side (outer) of the spar.

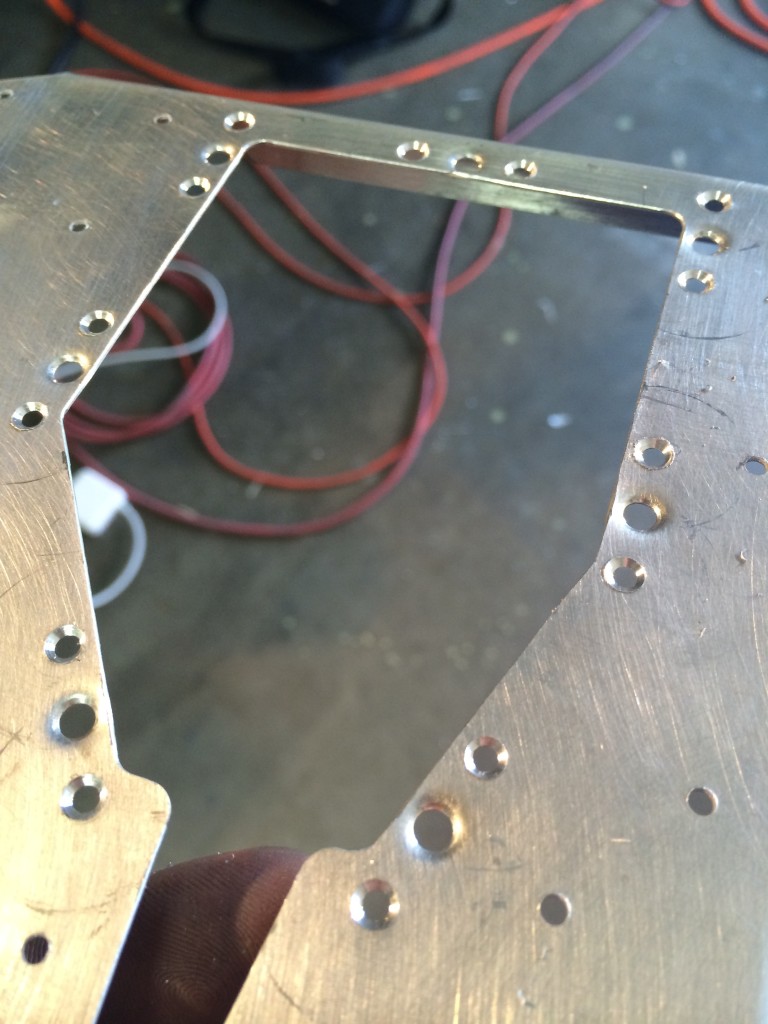

I had to machine countersink the nut plates holes in the trim reinforcement plate. Usually sheet metal of this thickness should be dimpled, but the nut plates do not allow for dimpling. In this case, machine countersinking is acceptable because the nut plates are only providing compression against the reinforcement plate.

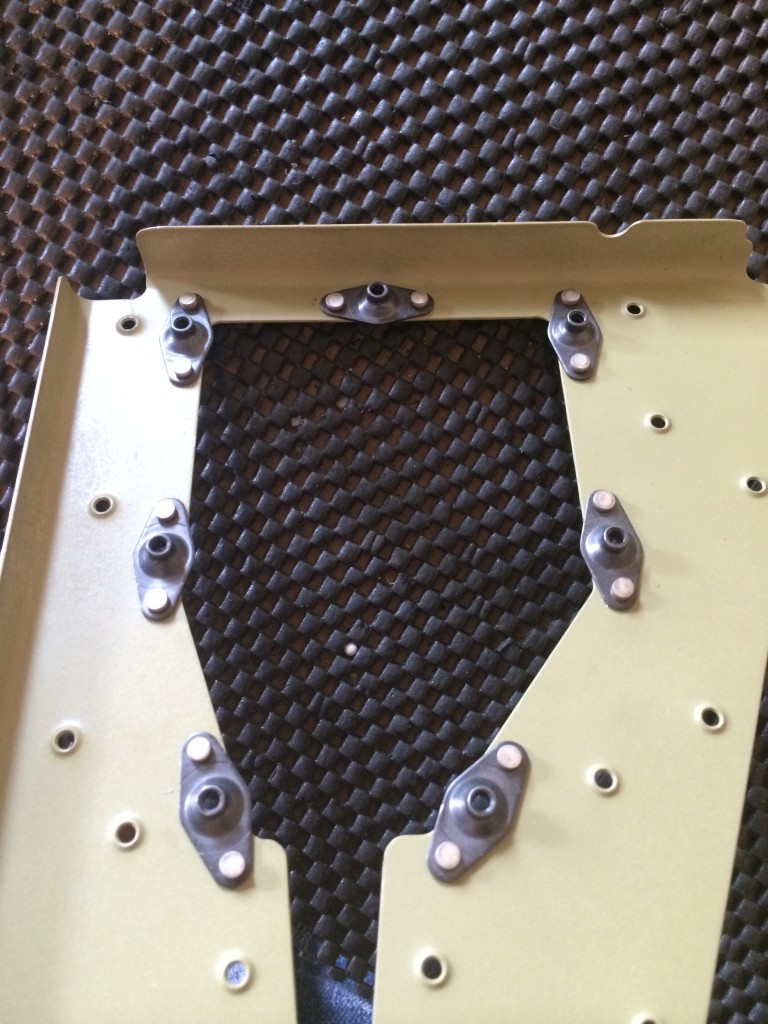

After priming the reinforcement plate I riveted the nut plates to the part.

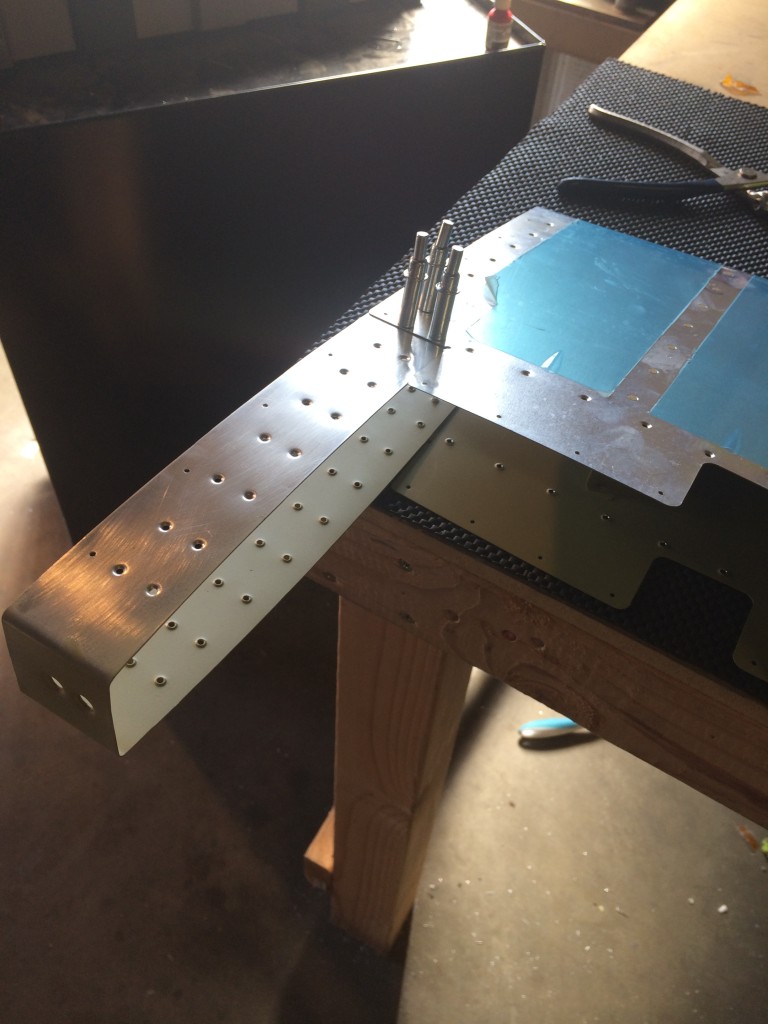

The reinforcement plate to the elevator skin.

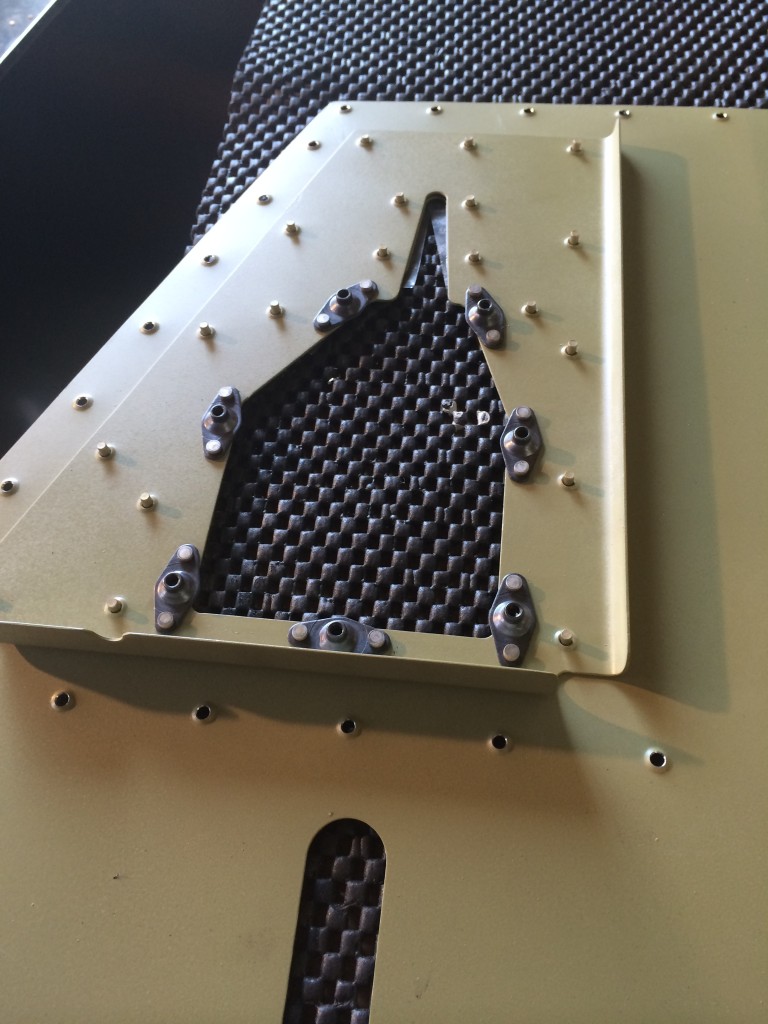

I riveted the counterbalance skin to the elevator skin.

I attempted to bend the closeout tabs around the trim tab. Due to the blocks being located too far inboard (and being a little aggressive with the rivet gun) I pretty much ruined the tabs. After doing some research, it looks like a ton of people have had this issue. I decided to cut off the tabs and just create a separate piece.I still need to clean up the area, but this should be a decent fix.The trim tab should be build first to actually determine the spacing between the tab and the elevator.