I started off the day by working on the trim tab. I bent the tab using the 2X8 bender–the bender is getting pretty warped and it should be replaced if any serious bending needs to be done in the future.

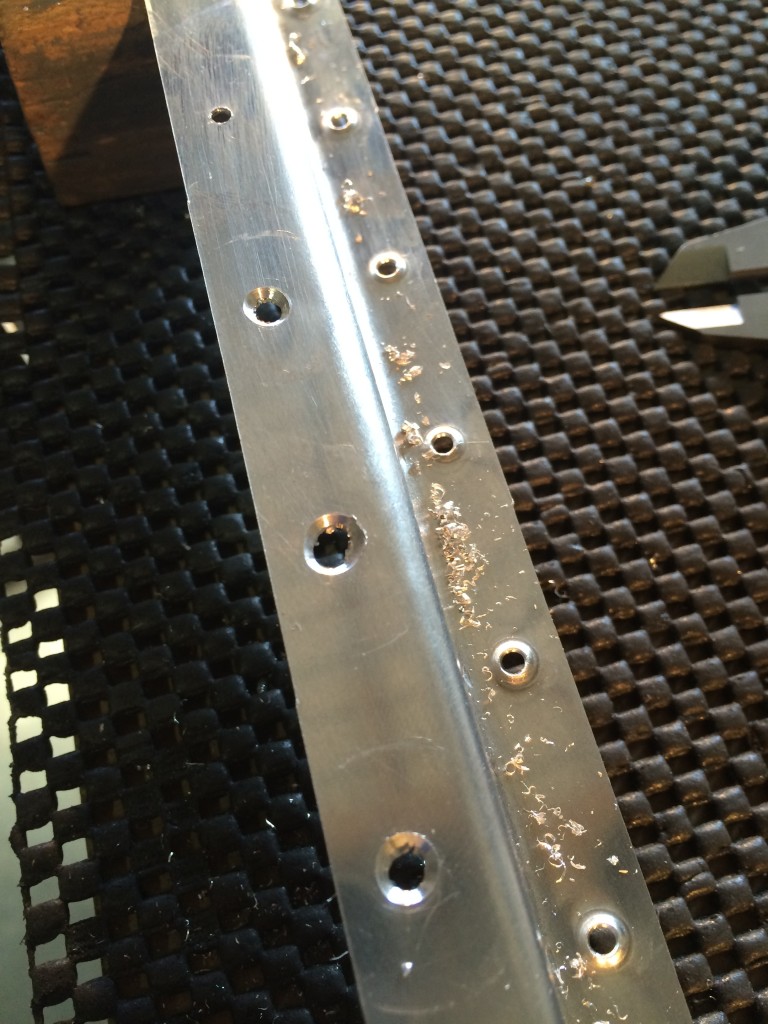

I need to replace the trim tab spar because the machine countersunk holes turned out really sloppy. Lesson learned: always have a pilot hole drilled in a backing plate when countersinking holes. I won’t be able to finish the trim tab until the new part is delivered.

I finished up my custom elevator closeout part. Overall, I think it looks pretty good.

I made a mistake on the trim tap cutout spar (goes on elevator). I dimpled the holes instead of machine countersinking them. I used my flush dies on the squeezer to flatten all the dimples. After that I was able to countersink the holes. I used some of the self-etching primer to seal the countersinks.

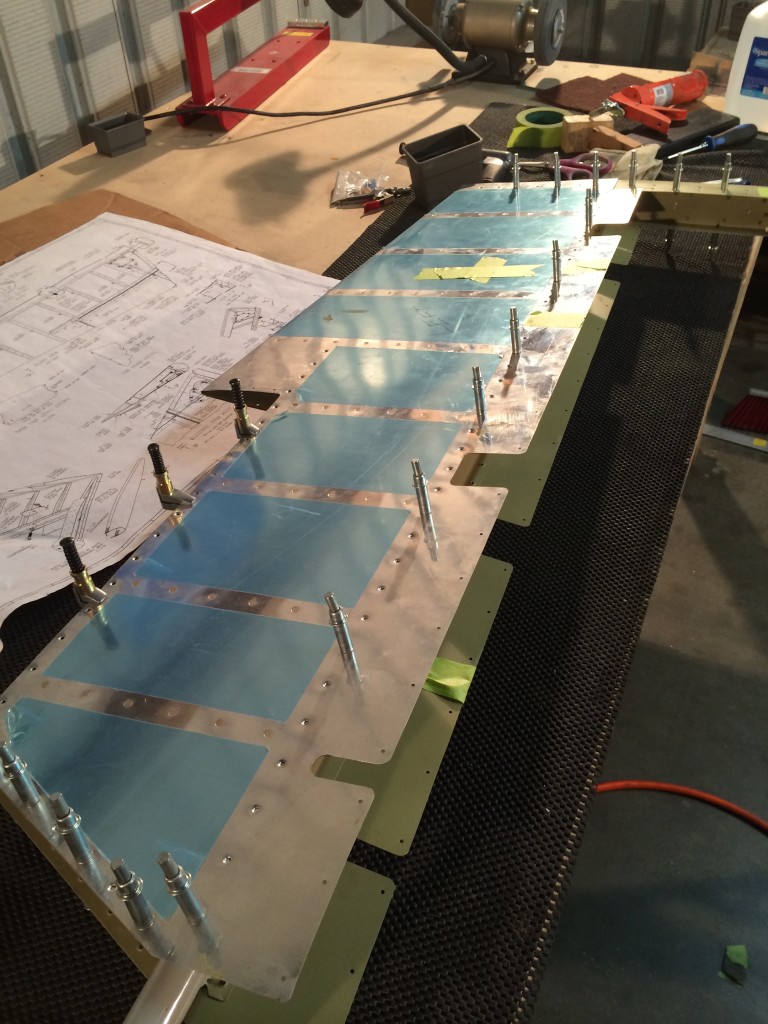

I riveted the skeleton to the skin–the end of the empennage kit is approaching!