I got the day started by fixing the oversight I made last time I worked on the tanks. I forgot to install the rib tip doubler. I deburred the doubler and match drilled it to the rib.

The rib was held in place with masking tape while I match drilled it. I used blind rivets to permanently install the part.

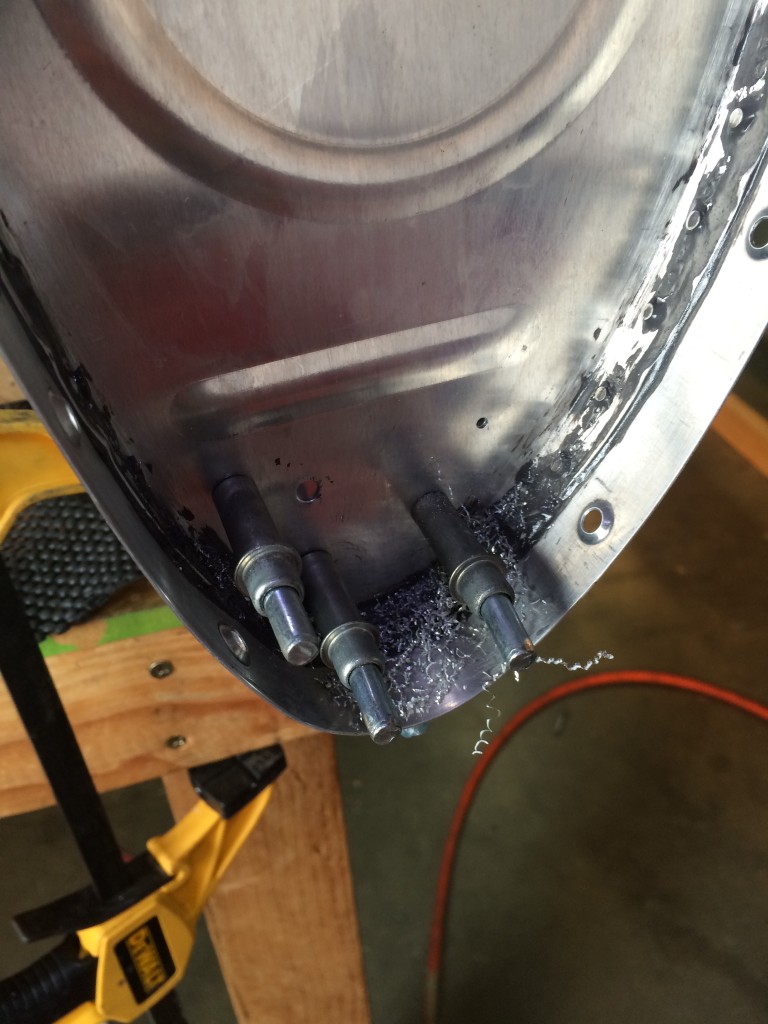

I installed the vent port and sealed the interface. The spec says the jam nut should be torqued to 45-60 in-lbs, so I torqued it to 53 in-lbs using a crowfoot.

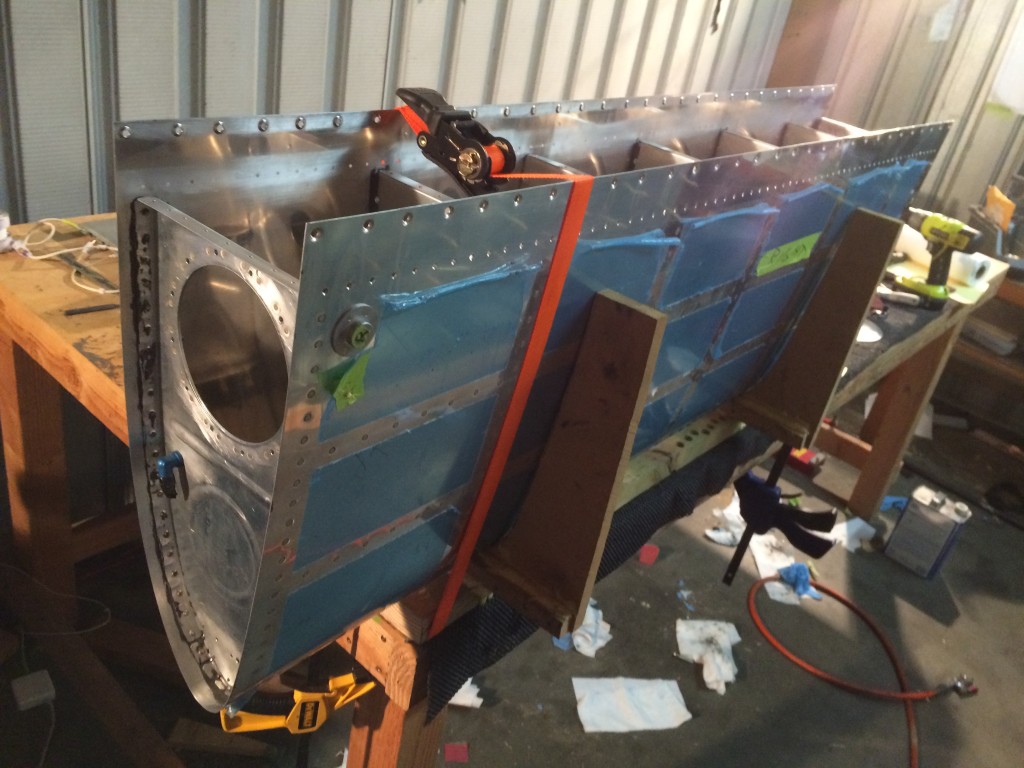

I riveted the inboard rib to the skin. The installation was straightforward.

The right tank is looking good! I was going to get the rib angle bracket and doubler installed, but the bracket interferes with the rivets. I’m going to have to add a chamber to the bracket to avoid interference with the rivets.

To finish up a productive day, I deburred the access port cover and the anti-rotation bracket.