Today is Monday. I took the day off work so I could focus on the airplane and take a break from work. I spent the day focusing on the left leading edge.

I started the day by finishing up some countersinking of the left leading edge skin. I also deburred the edges of the skin.

The next thing I did was cut the slot for the stall warning system. The image below shows the slot in work.

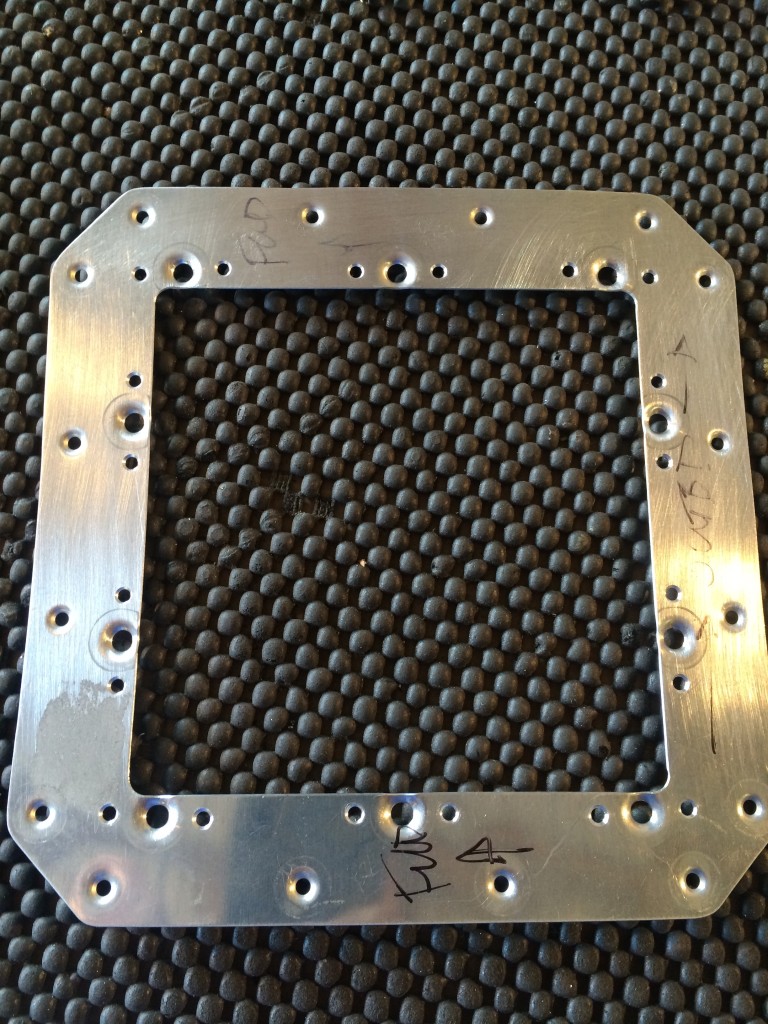

I did all the deburring, dimpling, and countersinking on the access cover frame.

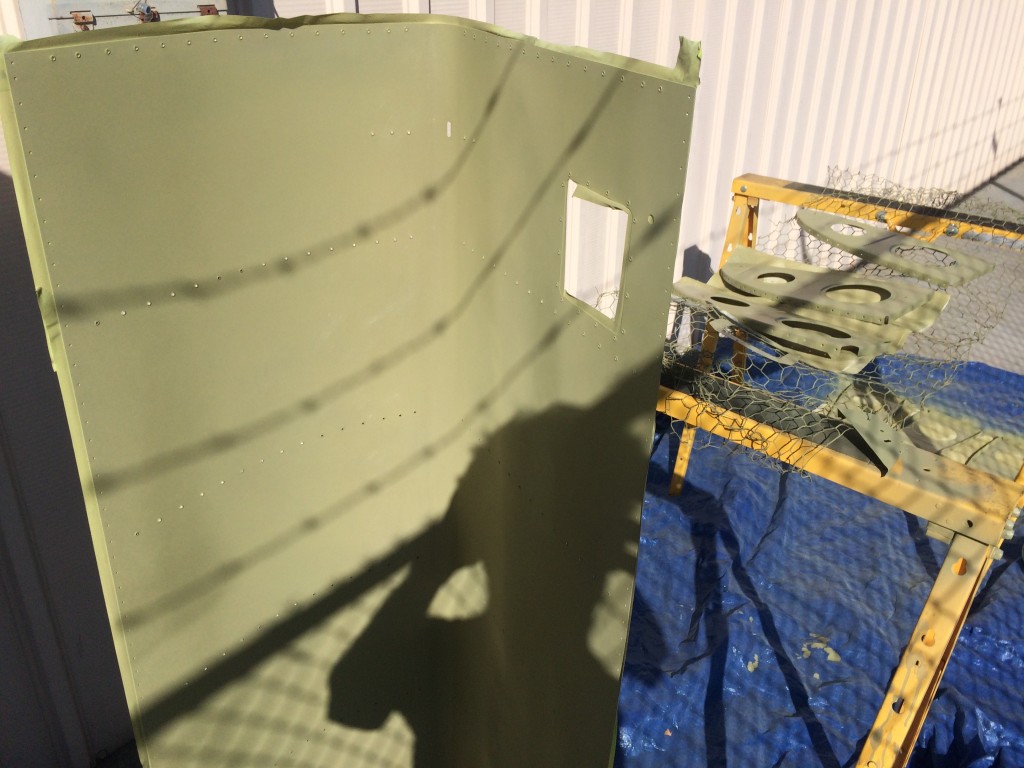

It’s been a few months since I’ve primed anything. Priming is a pain, but it’s part of the job. The quality of the primer on the skin was not great so I had to go back over it with the rattle can primer.

While I was waiting for the primer to cure, I jumped ahead and countersunk all the holes on the spar that will be interface with the outboard main skin and leading edge skin. I drilled the holes on the top and bottom sides of the spar.

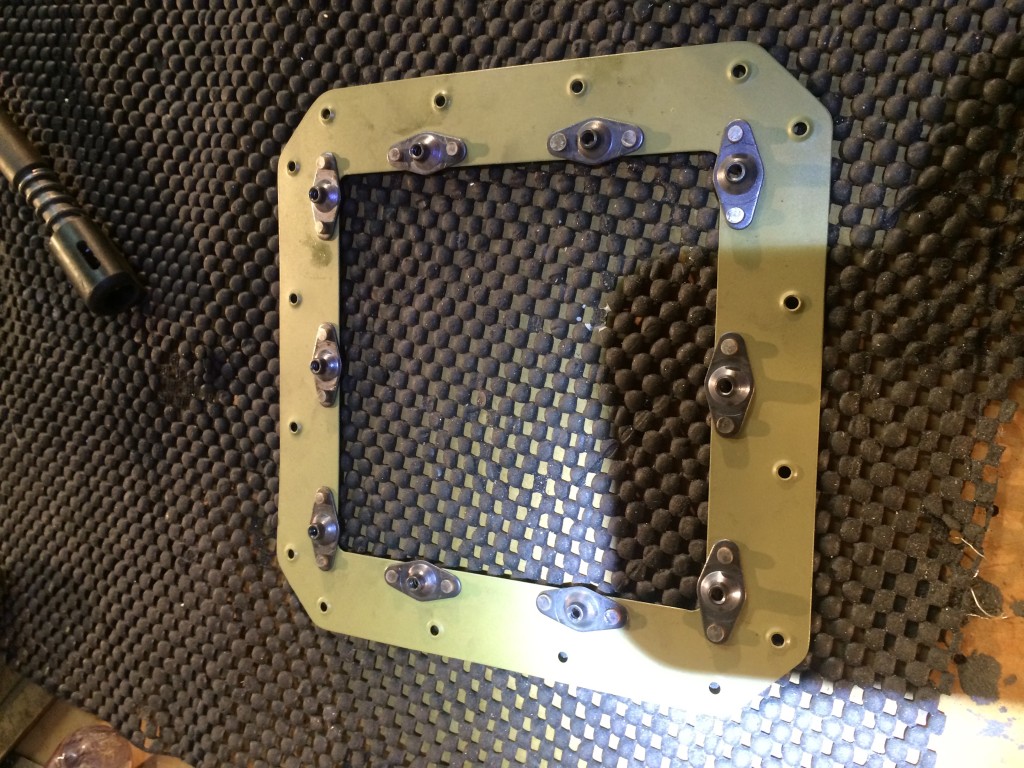

I back riveted the nut plates to the access hatch frame. The nut plates had to be secured with Oops rivets because the skin is too thin for regular rivets.

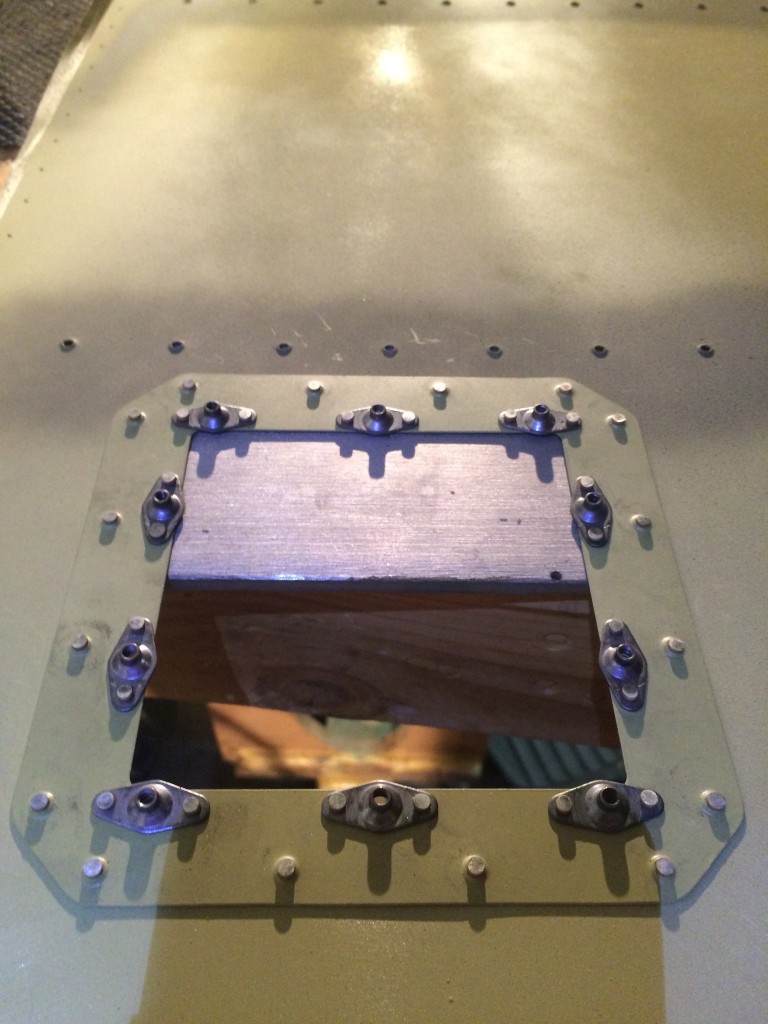

I back riveted the access hatch frame to the skin.

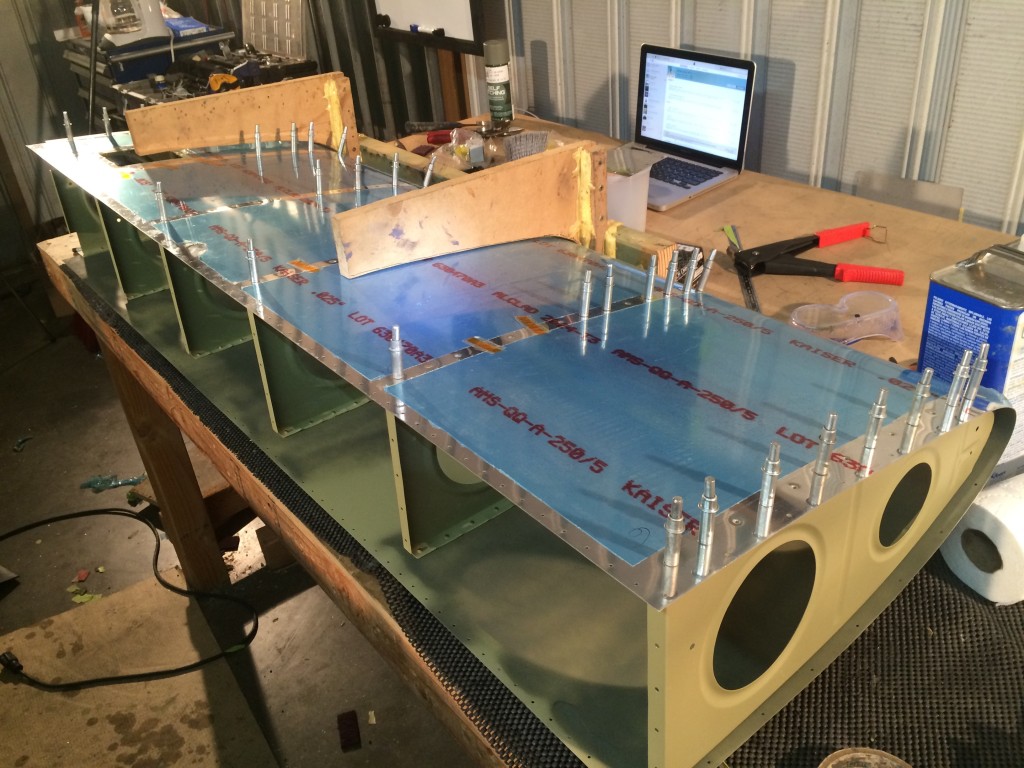

I started riveting the ribs to the skin. I got about one third of the rivets installed before calling it quits. I’ll finish the riveting job next time I go in.

I put in about 9 hours of work today. Too bad I can’t make this kind of progress everyday!