I spend the majority of my time getting all the miscellaneous work addressed before I move the wings to the holding fixture.

One of the minor issues that’s been annoying me is the “pillowing” of the sheet metal between the fuel tank and leading edge. The metal is flush where the fasteners apply compression, but “pillows” in the area between the fasteners. To solve this issue, I used an edge rolling tool to apply a slight bend to the metal. Removing the tanks from the wing was a pain, but it looks much better now.

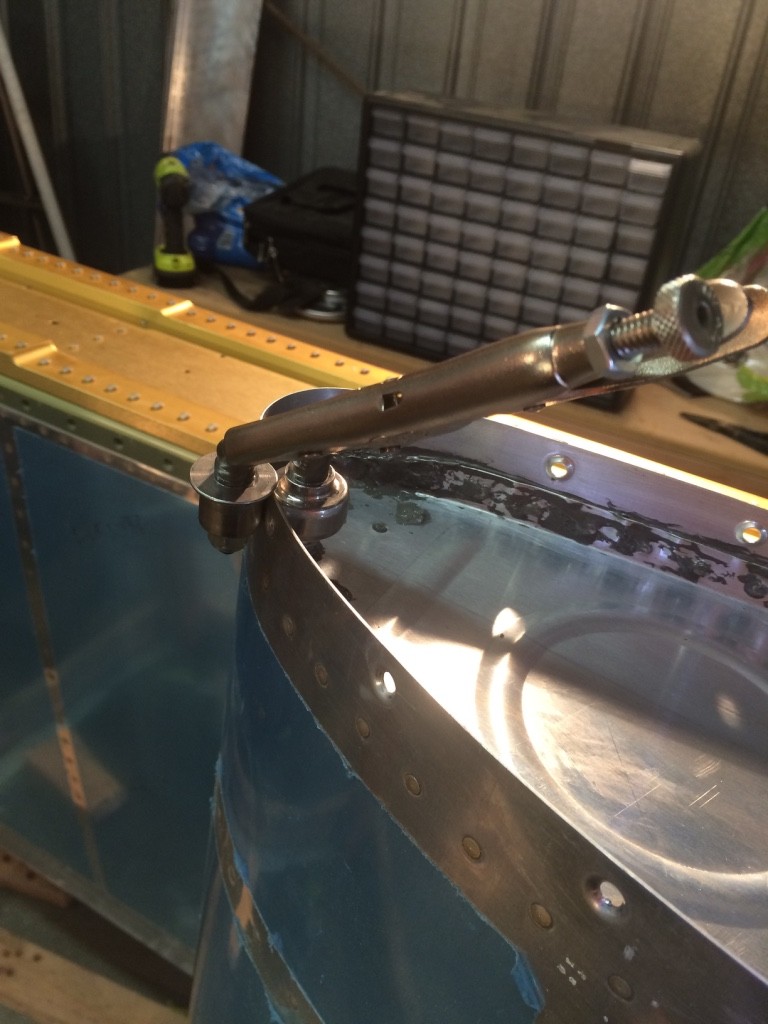

I installed all flat head screws and I torqued all bracket-to-spar fasteners to 30 in-lb.

The last this I did was a detailed inspection of all rivets. I had to drill out a few rivets and a few will have to be set a little more.