I only worked for about 2 hours today, but I stared on the milestone of bonding the rudder trailing edge.

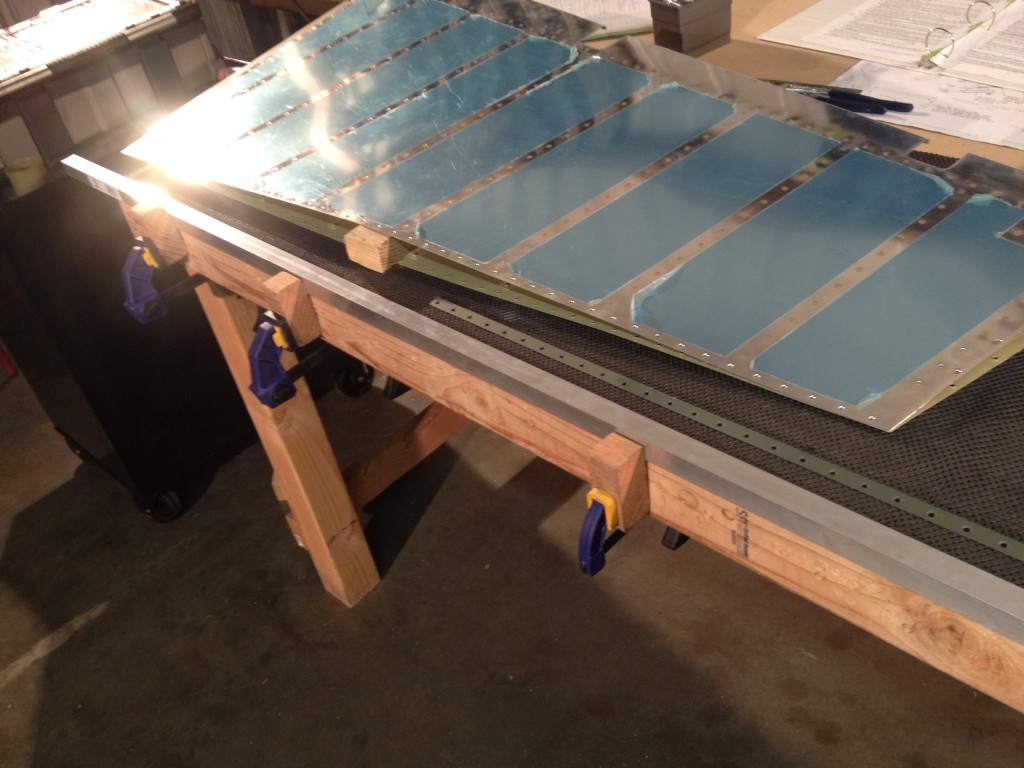

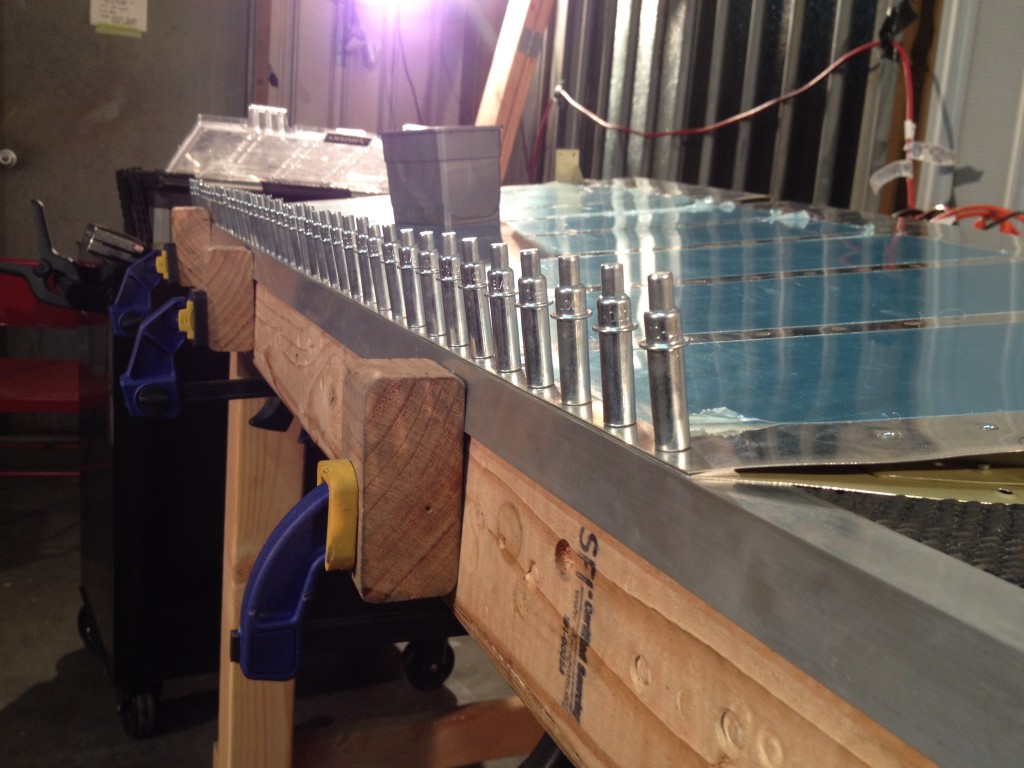

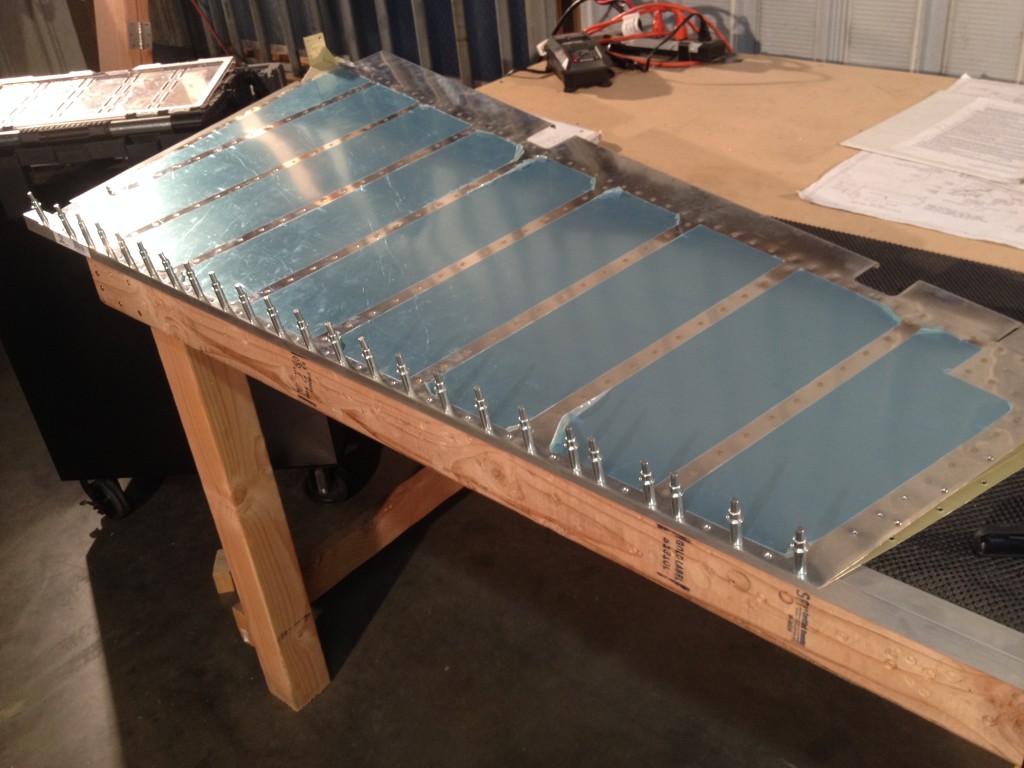

I matched drilled the rudder skins to the aluminum angle. It turns out and aluminum I bought was not straight. Also, the work bench sags a little in the middle. Between using the clamps and a long ruler, I was able to mount the angle to an acceptable flatness.

After drilling the angle aluminum I primed the wedge. Since I was only priming one part, I used the self-etching primer.

I applied Pro-Seal to the wedge and fixed everything with clecos. The Pro-Seal had to be cleaned out of a bunch of the countersinks. I suspect this will be an issue when I have to rivet the trailing edge.