Today would turn out to be a major lesson learned because I found out I drilled the nut plate holes slightly off from the correct location. I don’t believe this was caused by carelessness on my part–I problem stemmed from unclear assembly directions and my lack of understanding regarding how to Z-brackets fit between the spar and fuel baffle. After reading a few builder logs, it sounds like this is a common problem area. All work that was done today and yesterday will have to be redone. No big deal in the grand scheme of things.

Here’s what i actually did today:

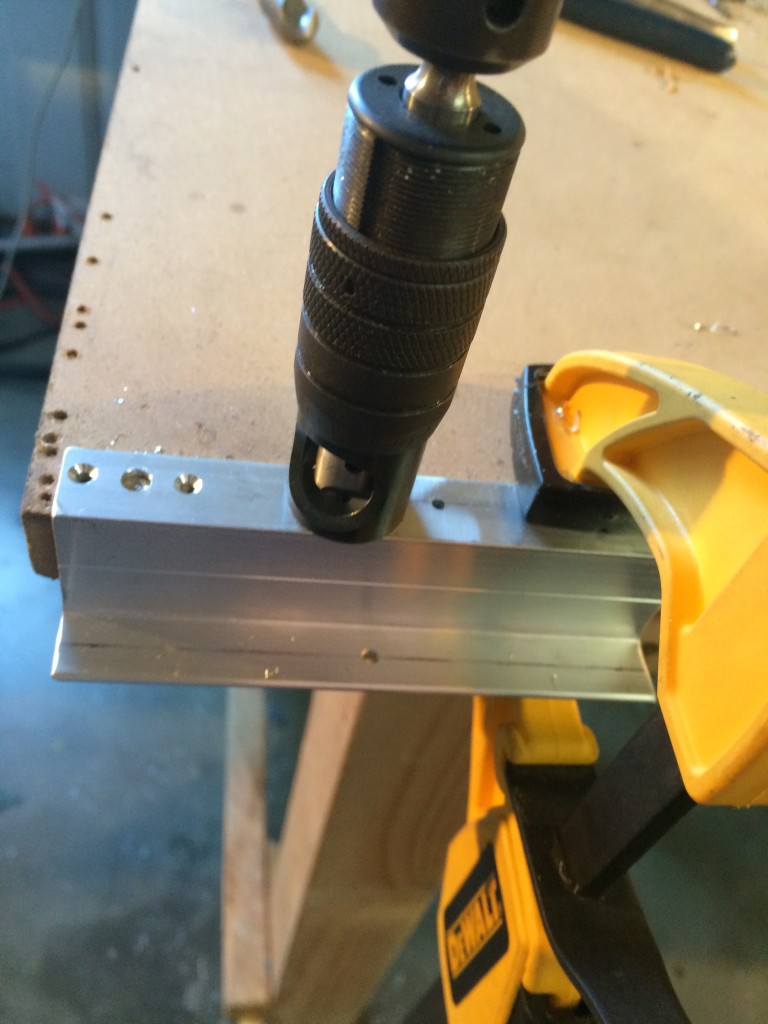

The nut plates were used as a drill jig.

The holes were countersink with the countersink cage.

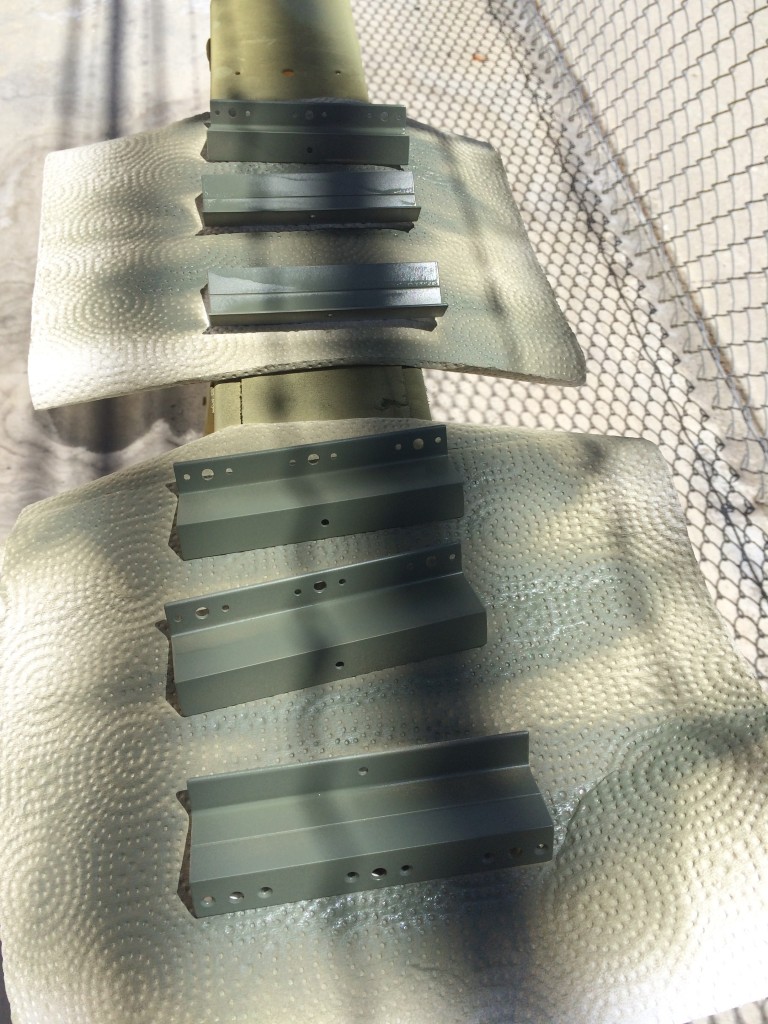

The parts were primed. I decided to just use the self-etching primer to make this quick.

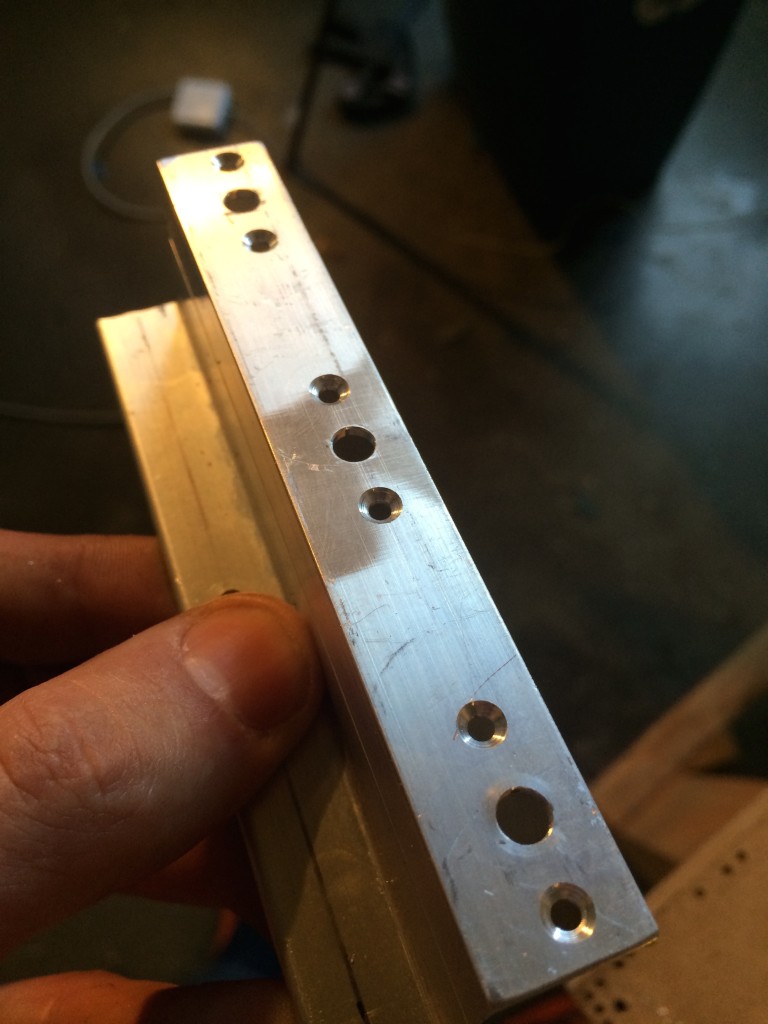

I used my pneumatic squeezer to set the rivets.

The final product. I made 6 of these brackets.

It wasn’t until I got to this point that I found out my Z-brackets don’t properly align with the fuel baffle (not shown). I’ll need to buy new brackets and redo everything. For the next go-around, I’ll match drill the baffle and Z-brackets together.

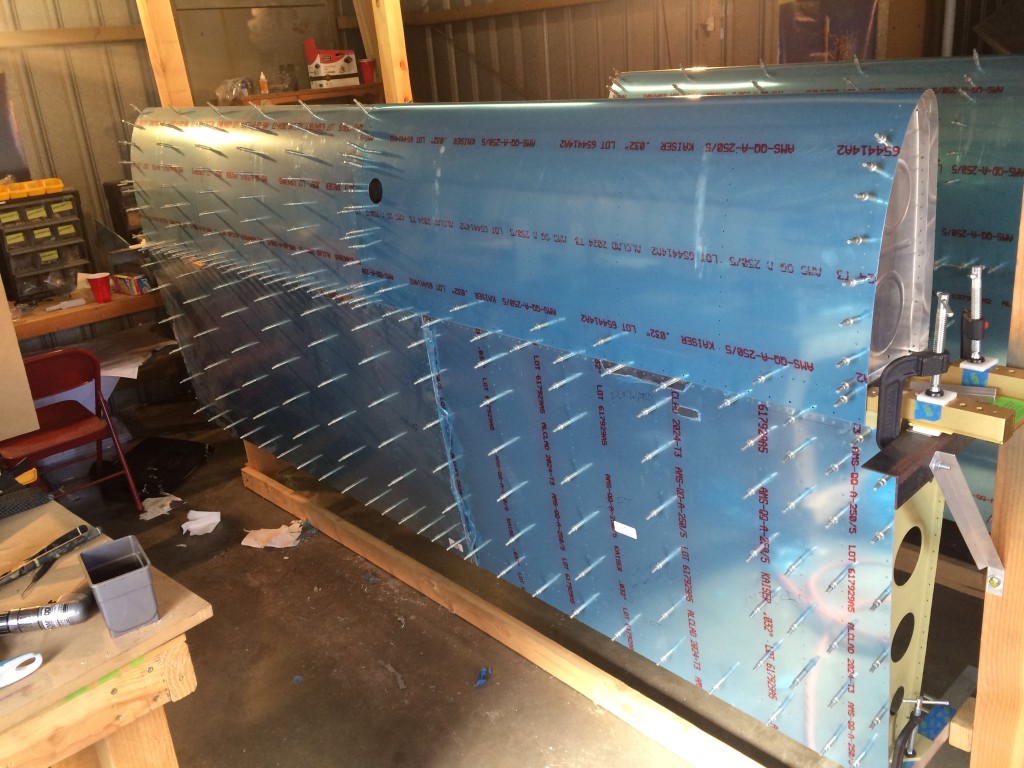

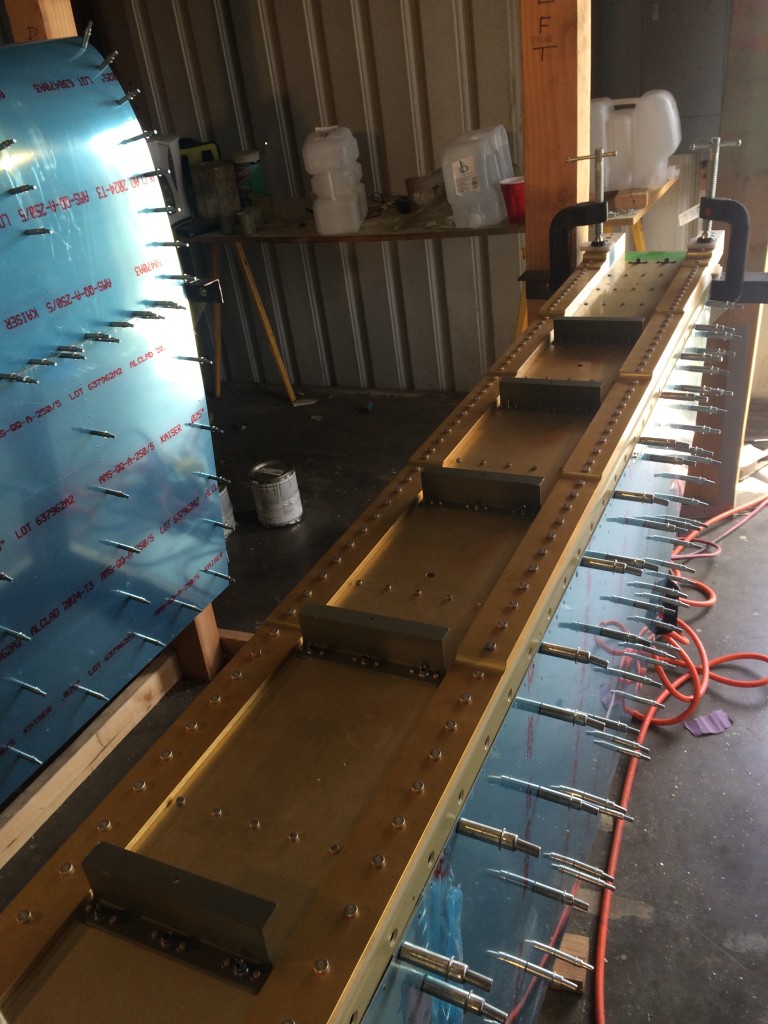

This is a random picture of the fuel tank skin installed on the wing structure. Of course, a ton of work will have to go into preparing the fuel tank assembly before the actual installation.