**I’m writing this update from London, which is pretty cool (the date I’m writing this is 01/02/2018 at 12:18am London time).

This was a short day because I have to get on an airplane to London in a few hours. My main goal was to add the left scallop to the bottom flange of the F-704 bulkhead, which is required for the tricycle landing gear configuration. To get started, I lined up the F-772 bottom skin with the F-704 bulkhead and marked off the exposed area of the flange. You can see the flange section (colored black) highlighted in the image below.

Here’s the flange marking after removing the bottom skin.

I used my Dremel to remove the majority of the flange material. Getting the scallop looking right took a lot of checking against the landing gear weldment.

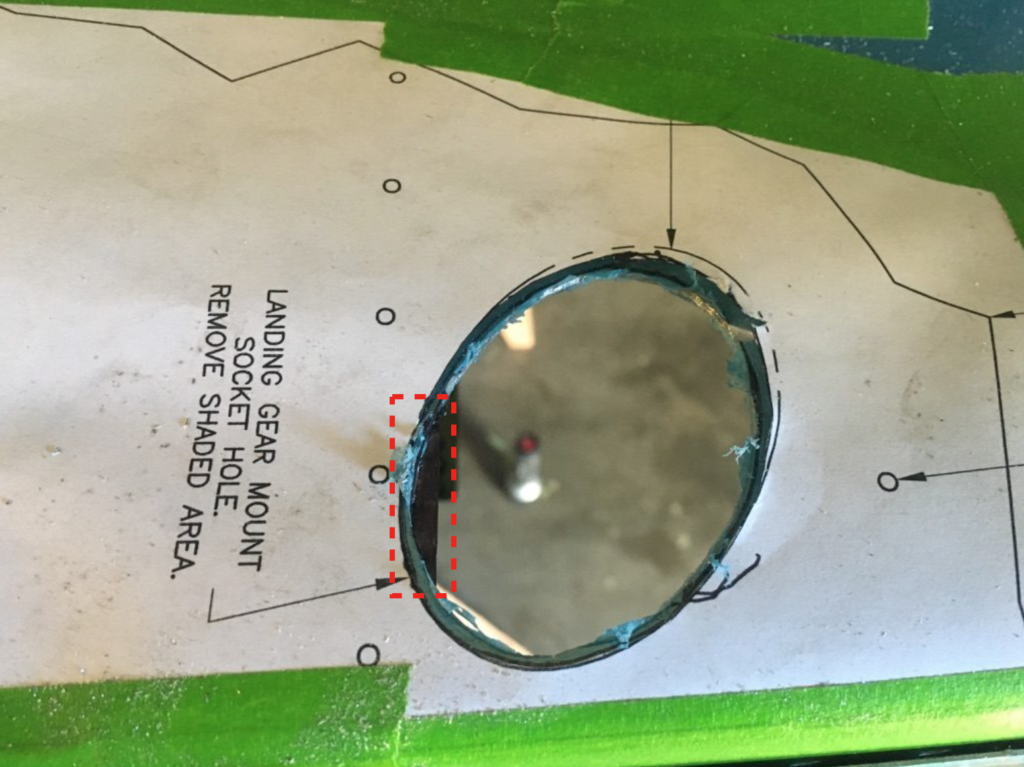

Here’s the final product. I want to take another look at the fit, but I’m pretty happy with the results. The edge distance violation around that hole is common across all tricycle versions of the RV-7. It’s not ideal, but there’s nothing that can be done.

You can see the fit against the weldment in this picture. The goal is to provide cleanance around the weldment, but not remove more material than necessary. The hole distance requirement has been violated for the hole closest to the scallop, but this is standard practice in this location.

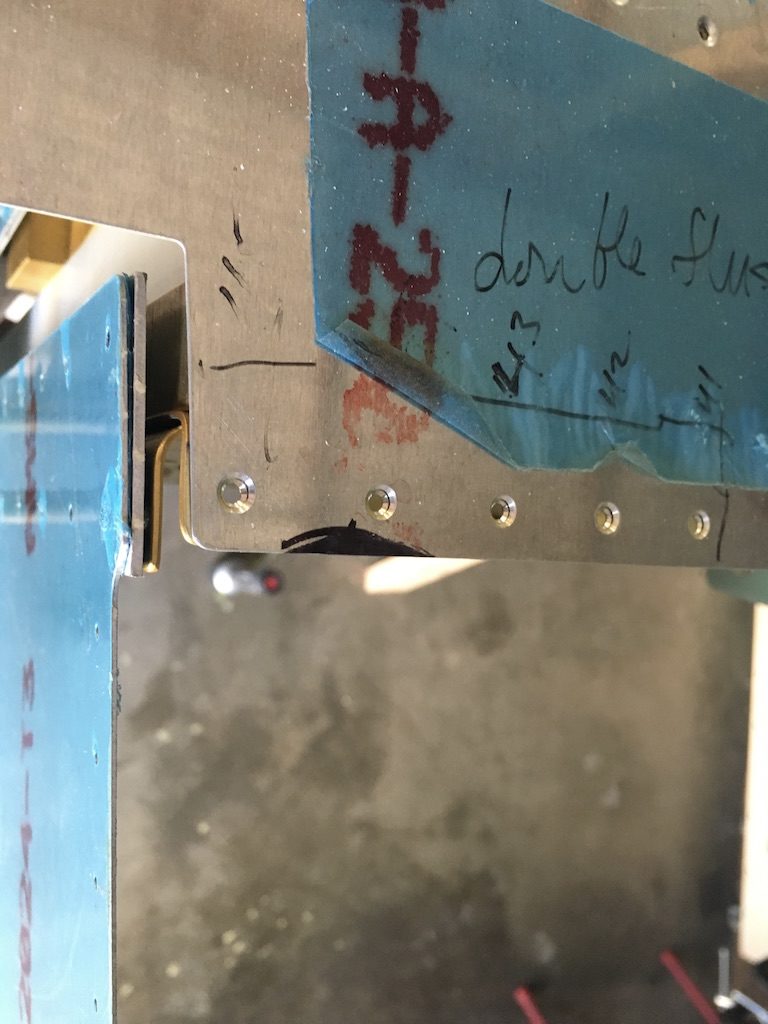

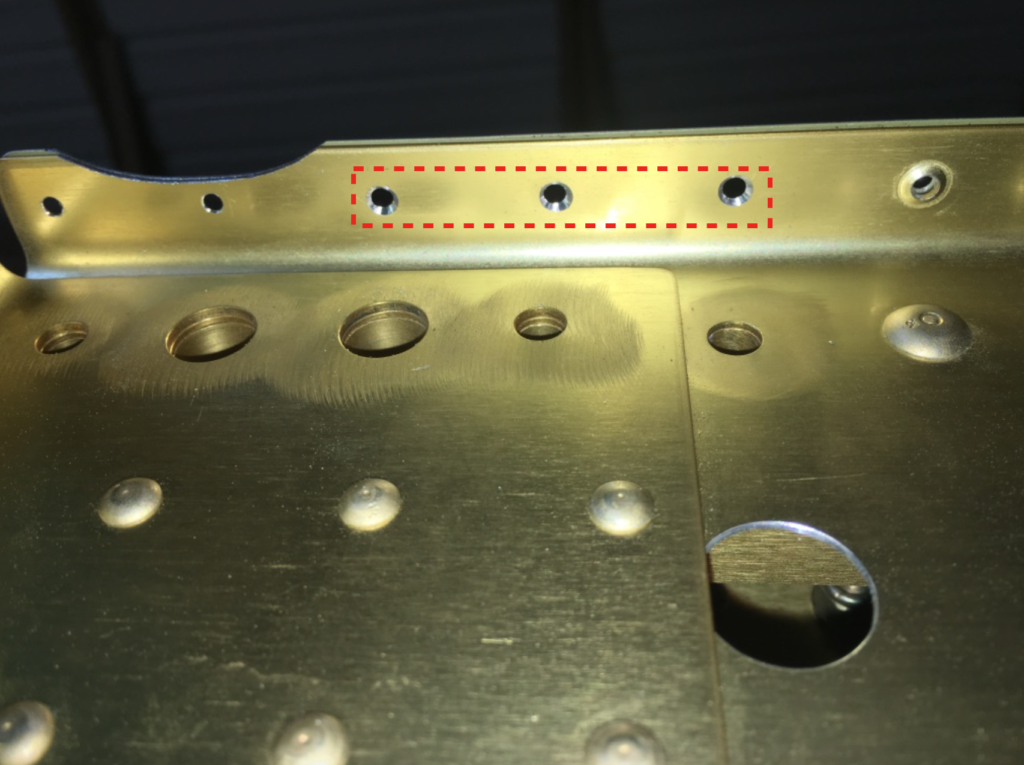

When I had originally dimpled/countersunk the F-704 flange holes, I didn’t add the inner countersink on the outer 5 holes on each side of the flange. These holes should be double-flush to avoid the rivet contacting the landing gear weldment. I cut 3 of the 5 inner countersinks on the left side, which you can see in the image below.

Here’s the tool I used to cut the countersinks. I used the normal 3 flute #40 countersink bit threaded into a shaft. The shaft came from a rivet removal tool I had cut apart like a year ago. The countersinks were cut into the flange by just spinning this tool by hand. I had to continuously cut away small amounts of material and compare the countersink against a flat head rivet.