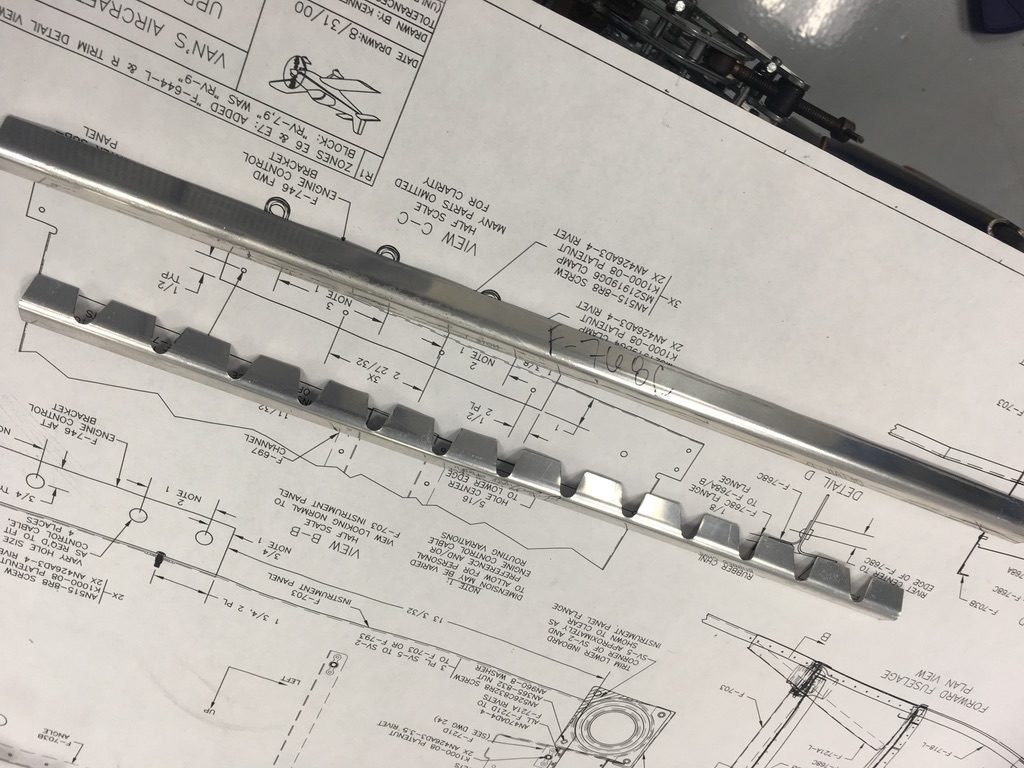

I knocked out the cutting of one F-768D seal support angle. Getting all those tabs cut took some serious time. After drilling the holes (shown below), I used sheet metal cutters to remove wedge section of material. The material is thin enough that the metal experienced minimal warping from the cutters.

This image shows the final product. I still need to clean up the edges, but the angled turned out great. I was also able to knock out cutting the F-768C angle. This just involved cutting the part to the specified length.