[<<Prev] [Next>>]

As usual, I’m jumping around in the plans to work on the areas that I think are a little easier to handle in shorter bursts.

This first thing I did today was countersink the top surfaces of the longerons. This area interfaces with the top deck. When it comes to cutting the parts that are already riveted to the fuselage subassembly, it’s critical to triple check everything. I’m not sure what I would do in some in some cases where the incorrect area of the fuselage was cut. I’m going to go back over these holes JetFlex next time I have a paint job.

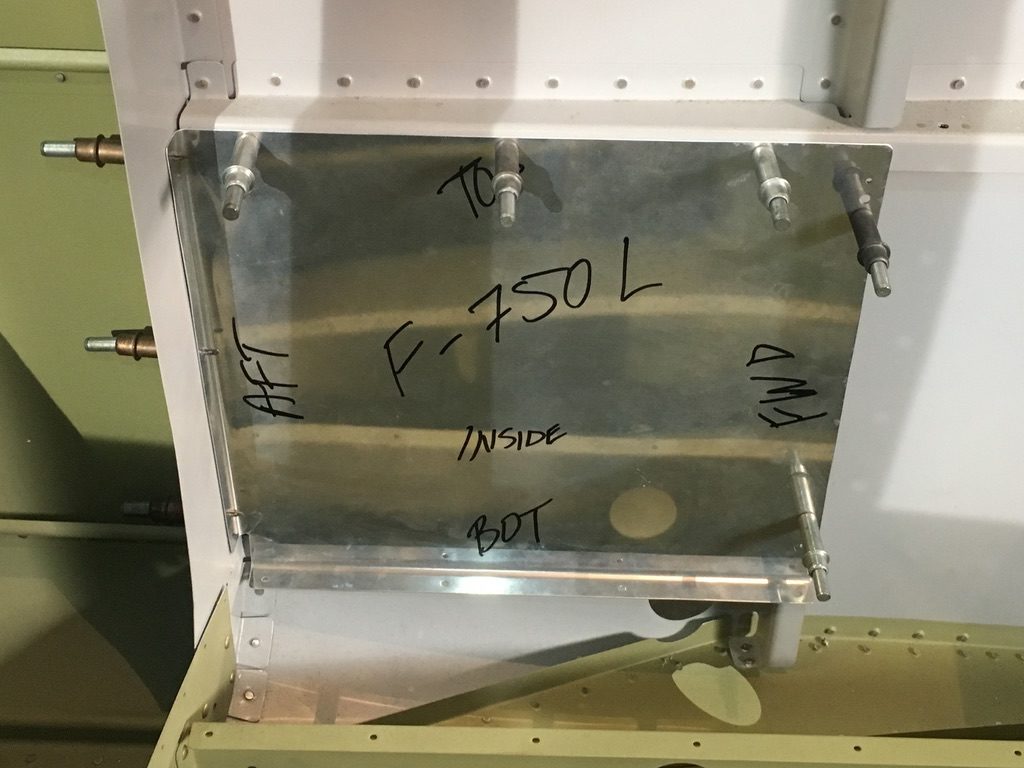

I got the F-750 Aft Baggage Side Covers clecoed in place. I’ll match drill these parts next time I’m the hangar.

Fo those builders installing the step kit, the plans tell you to do this after the aft baggage panels are riveted in place. This is incorrect. You need access to the inner surface of the skin to set the rivets, which means the steps should be installed prior the the aft side panels.

This is what the side step looks like when you drill the mating hole to the diameter specified in the plans. The weld around the tube prohibits flush mounting. Some internet research shows that other buildings just remove the interfering material around the hole. I’ll take care of that next time I go in.

Test fitting the step shows the tube is about .250 inches too long. I taped off the required tube length and ground down the excess material.

[<<Prev] [Next>>]