It’s been weeks since I’ve gotten a solid day on the airplane. Fortunately things have calmed down slightly at work and we successfully recovered the the Demo 1 spacecraft.

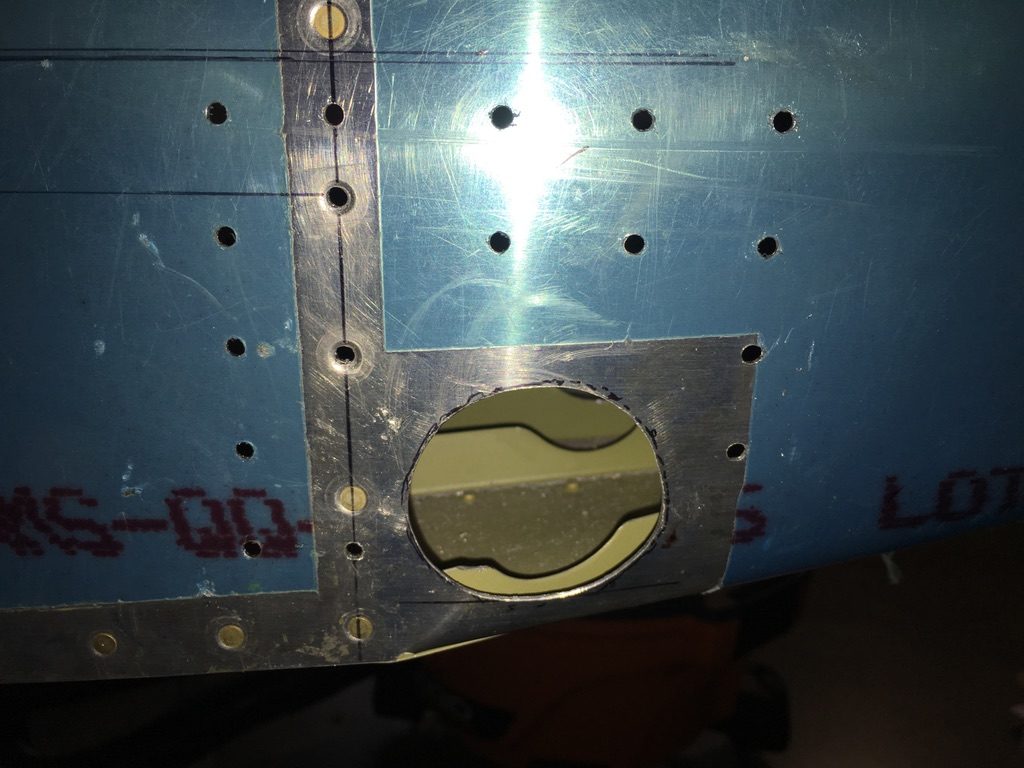

I used this time to accomplish most of the installation work on the left external step. The first thing I did was open up the outer skin hole size to accommodate the weld around the tube and the baseplate. I also trimmed down the step tube length so that it’s nearly in contact with the F-726 rib.

The baseplate was match drilled to the fuselage skin. To get the baseplate to match the curvature of the fuselage, I clamped the plate in a vise and used a combination of a hammer and crescent wrench to form the plate to the appropriate shape. This took quite a bit of guess-and-check.

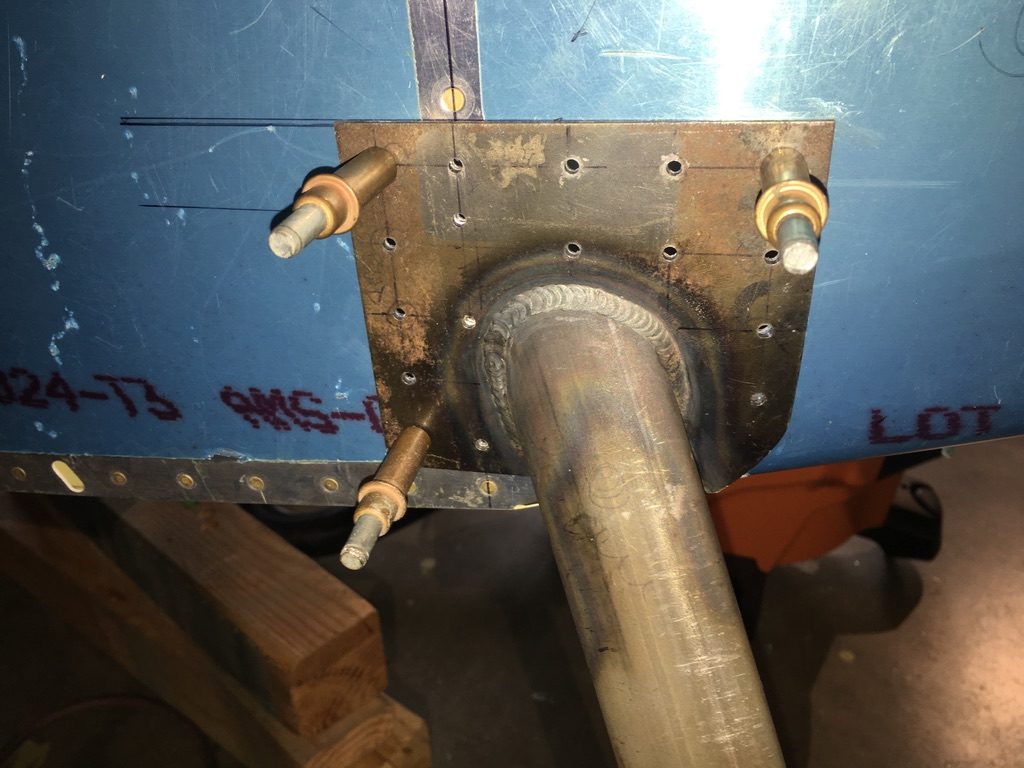

This image shows the external step mounted against the fuselage. I used the rivet line of the F-724 bulkhead as the guide to orient the step. The top of the baseplate is 90 degrees to the rivet line. When drilling the holes the pass through the bulkhead, I removed 2 rivets and backdrilled the plate.

You can see where the 2 holes were back drilled. I’ll try to flatted those countersunk holes before I rivet the step in place. This whole drilling job came out really clean.

The last thing I did was match drilled the UHMW block to the tube and the rib. I kept things clamped up to prevent any movement.

Welcome home Crew Dragon! The achievement that occurred yesterday was the result of a ton of hard work by the SpaceX team. It feels good to have my hardware on the world’s newest human-rated spacecraft.