Finally I’ve gotten a solid day at the hangar. It feels like I’ve been just spinning my wheels on this portion of the project for many days. The right side of the canopy frame was fitted and drilled. This was a ton of fitting, checking, and re-fitting.

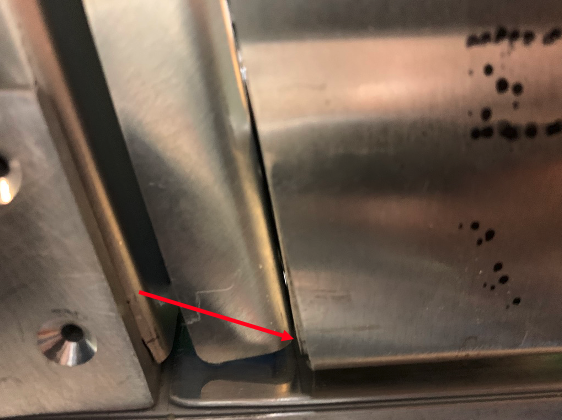

I noticed the welded angle bracket didn’t align with the sheet metal canopy frame side. In the picture below, you can see how the sheetmetal aligns with the channel, but the bracket does not. I sanded down the bracket so that everything was at the correct angle.

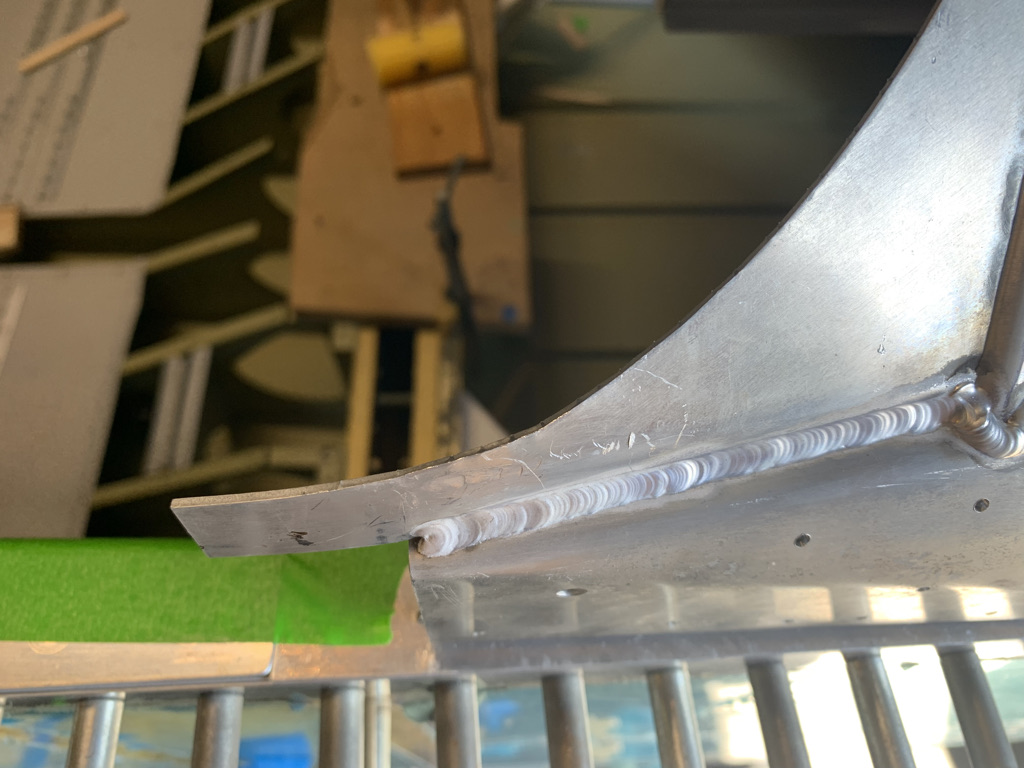

As the plans instruct, I smoothed out transition of the WD-716 around the upper edge.

You can see the see the transition from one part to the next in the image below. I also match drilled the C-613 Canopy Splice Plate to the side skin.

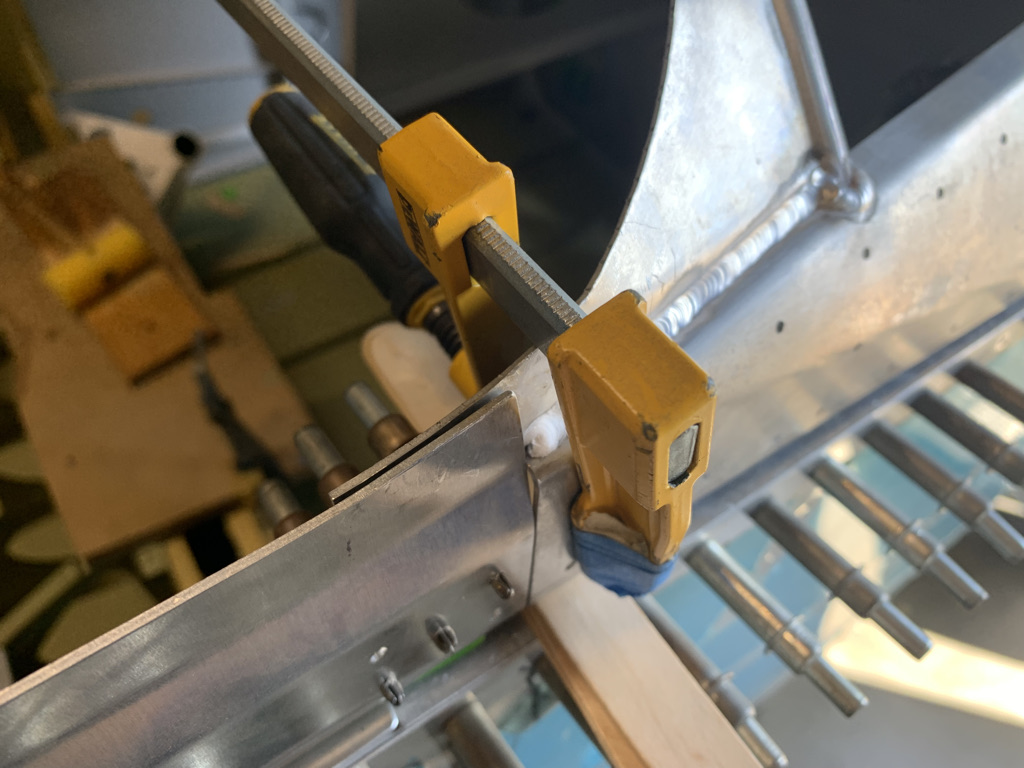

Getting the right side skin aligned between the forward frame and the channel took a good amount of time, but it turned out decent. The image below shows how I clamped the .032 thick sheetmetal in place to ensure things were properly aligned.

I got the angle bracket riveted to the channel. Those outer 2 holes are a bit close to the edge of the channel. I’m hoping this is not an issue. I won’t know until it’s taken off the fuselage.

The splice plate was drilled to the forward canopy frame.

Getting the canopy frame to this point was a ton of work. Now that I’m more confident in what I’m doing, the left side should go much quicker.