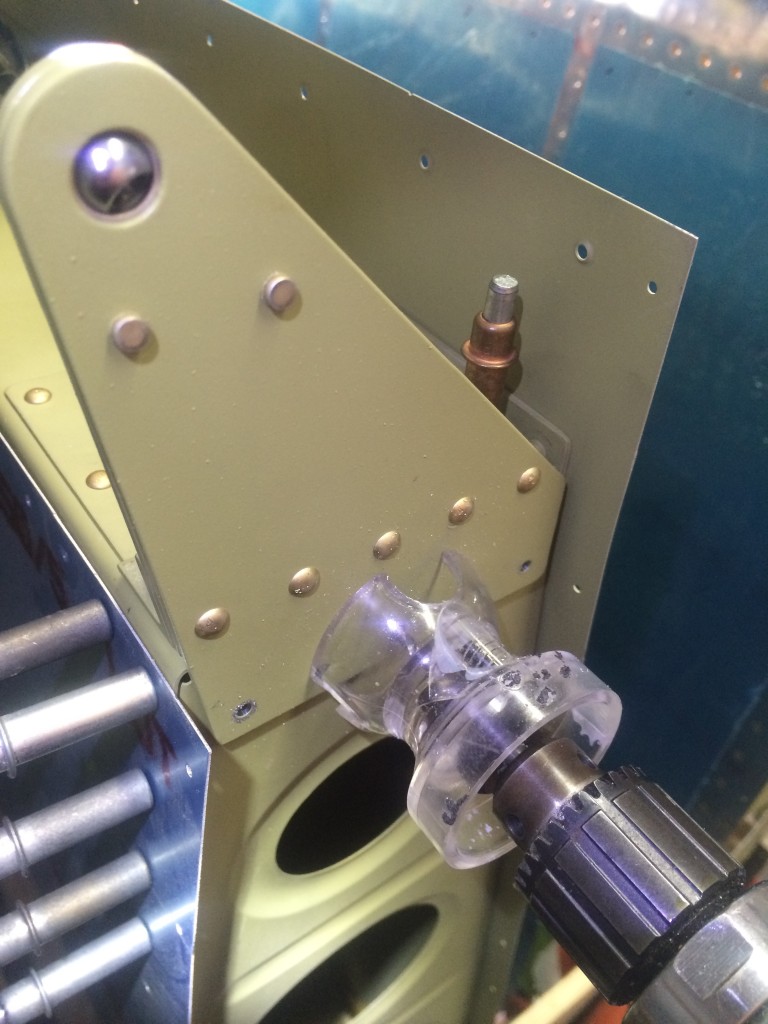

I got started by match drilling the outer right aileron bracket to the spar/rib.

The bottom rivets were squeezed, but the top rivets had to be bucked due to the reach of the yoke.

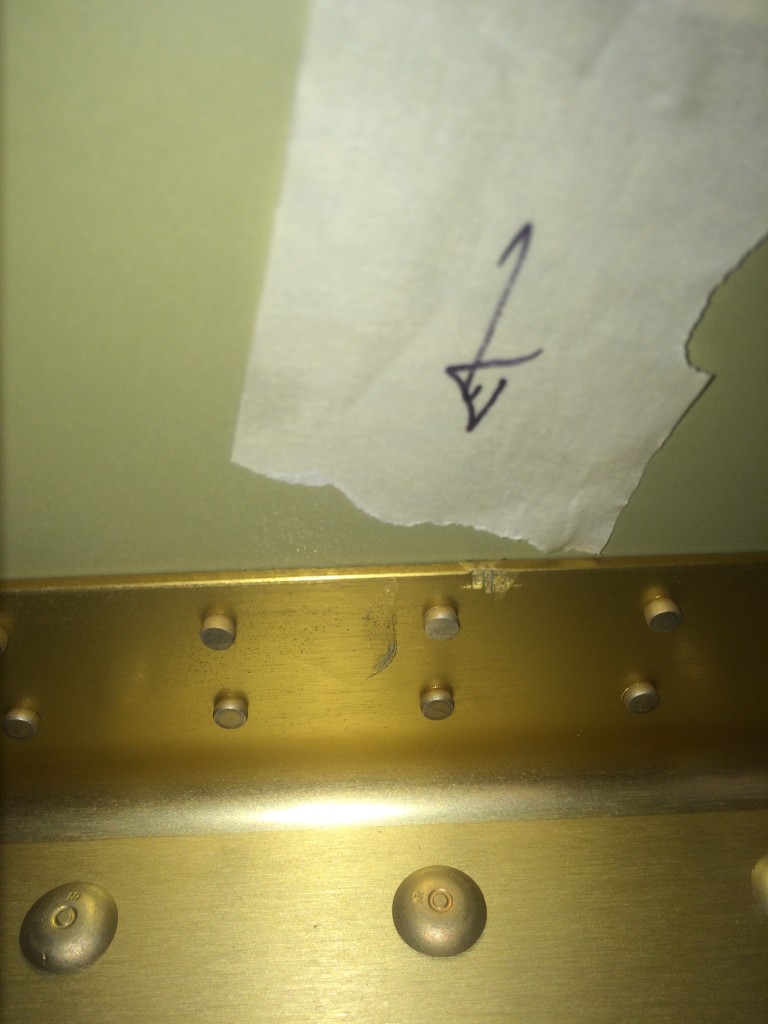

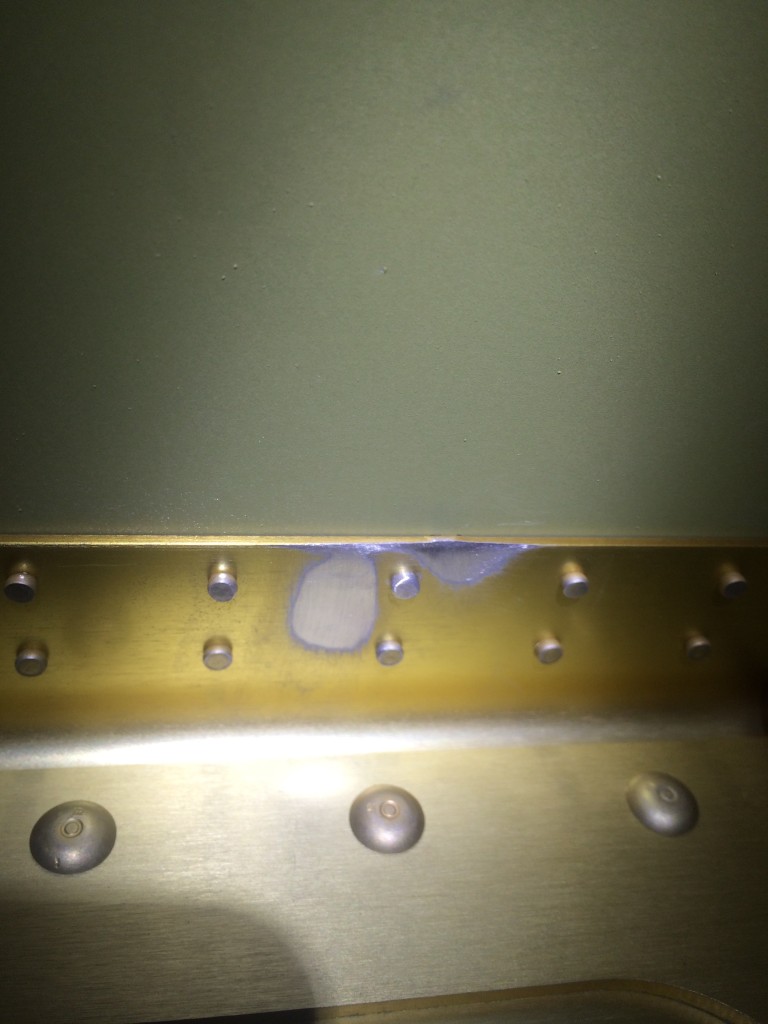

One of the outstanding issues on the right wing was the dent/scratch that was put in the flange of the spar. While riveting the skins, the bucking bar slipped off the shop head and dented the spar.

I used a few different types of sandpaper to blend out the dent. The parts look good now, but I’ll make a note to keep and eye on this region.

I installed the corrugated tube that will route the wing tip lights. This tubing took a ton of time to install due to the close fit of the tube/hole.

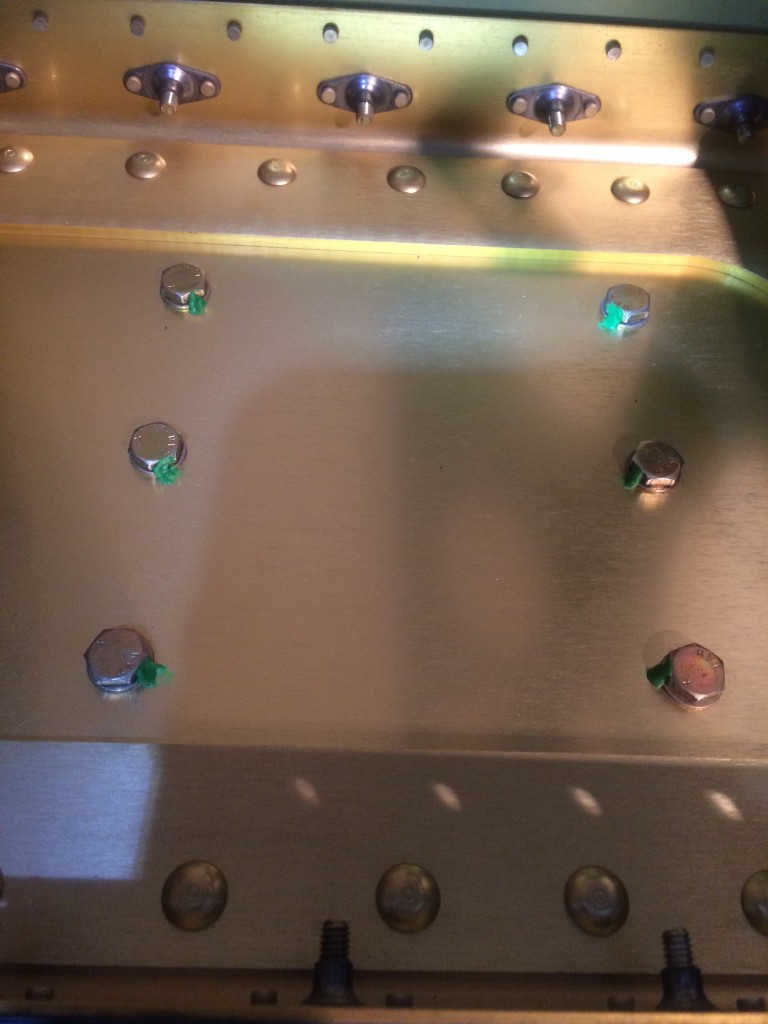

I torque striped all the fastener heads that secure the tank brackets to the spar.

I made a minor oversight when I riveted the aileron brackets together. One of the holes is supposed to be countersunk. Since it wasn’t really possible to get the drill/countersink in the proper location in the assembled state, I had to drill out the rivets.

I had to cut the countersink without the cage. This was pretty tricky, but it turned out fine. The key is just to go slow and keep the drill perpendicular to the surface of the part.

After riveting the brackets back together, I riveted the subassembly to the rear spar. I used my squeezer where I could, but the rivets closer to the top skin required the rivet gun.