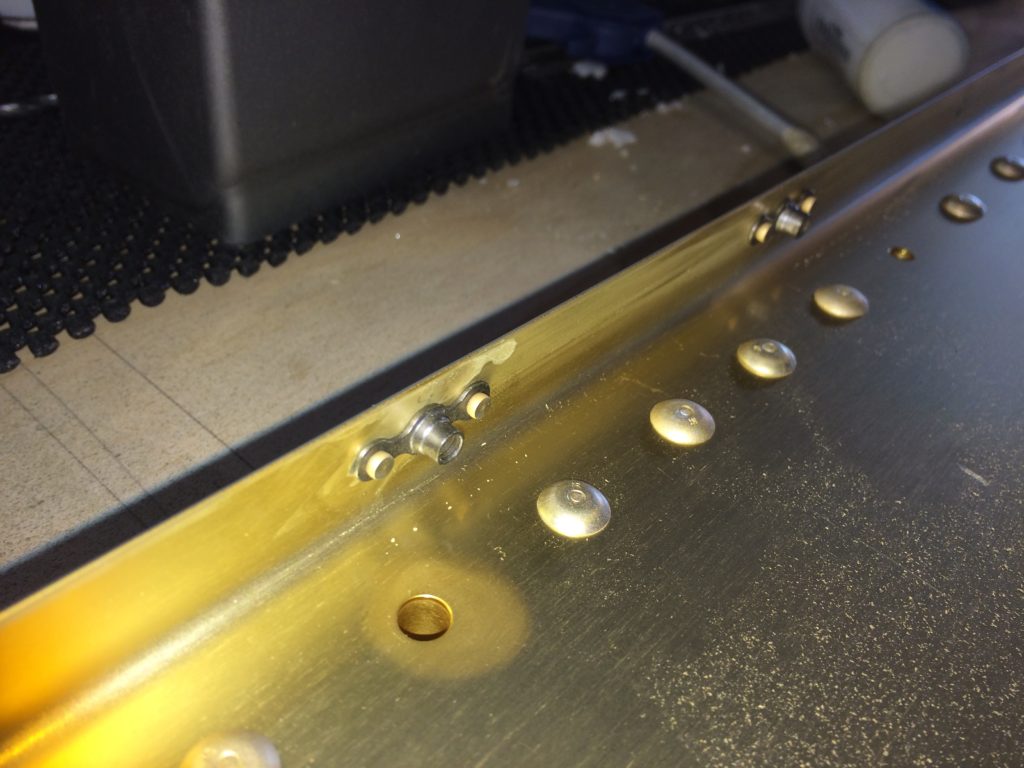

I got started by finishing up the riveting of nut plates on the center section.

There’s a ton of piece-parts that go into these bulkheads. I used my unibit to drill out the passthrough holes in the brackets.

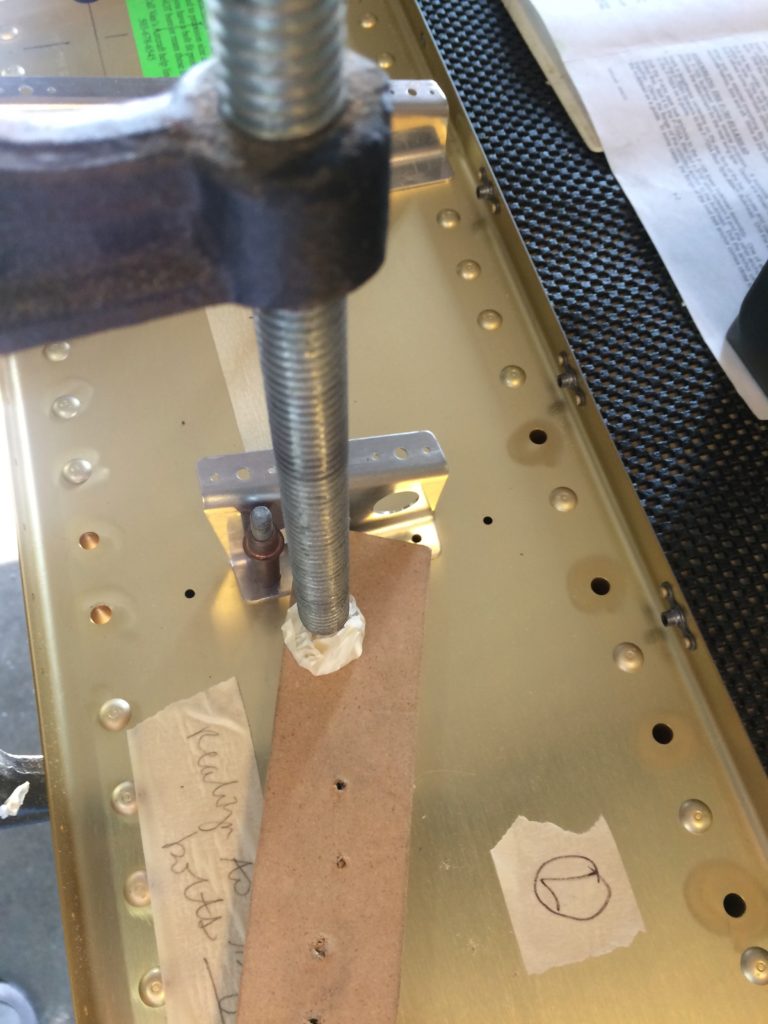

I use tape to ensure I don’t drill too far with the unibit.

I used a C-clamp to hold the small brackets to the center section while I drilled the parts. The holes were opened up the #19 bit size.

I used cleccos to hold the larger brackets in place while I drilled the top and bottom holes to #12 size.

Instead of moving forward with assembling the center section, I’m going to keep working on the bulkhead piece-parts. I used a band saw and file to cut the excess material on the F-705C doublers. The F-705 bulkhead is located directly behind the seatbacks.

I used the horizontal bandsaw at work to cut the F-705B bar.