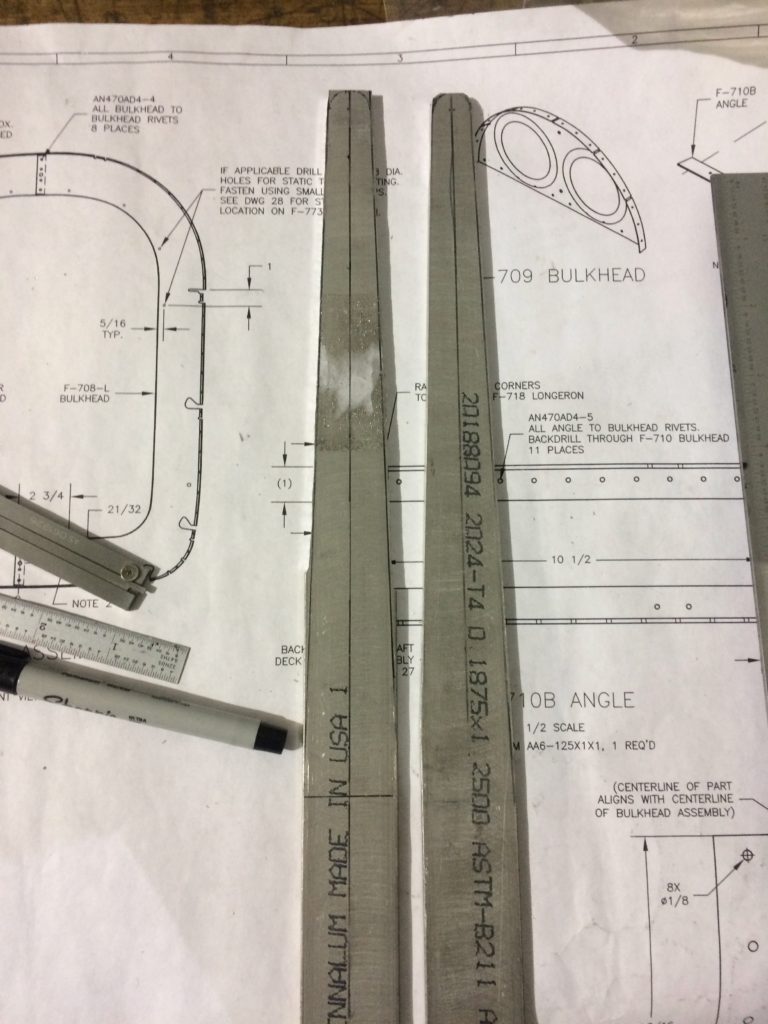

I brought some parts into work to make the necessary modifications. I’m jumping around in the plans, but all my work will add up in the end. For the aft tie-down bar, I used the horizontal band saw to cut it to the appropriate length. The vertical band saw and a belt sander were used to form the angled edges.

To tap the tie-down bar hole, you first need to open the hole to a diameter to .3125. To ensure my threads were aligned with the hole, I located the bar in a vise and used a tap located in the drill press. I manually turned the chuck to tap the hole.

I next jumped to the F-711 bulkhead. I used a bandsaw to do the rough cuts on the F711-C doublers.

For the F-705H spacers, I had the good fortune of using a mill to make the required modifications. I used the mill to cut the step in the spacer.

I used a bandsaw to separate the spacers. I cleaned up the cut surface with a pass on the mill. These little parts turned out very clean.