Most of this evening was spent preparing the center section for assembly.

For the tricycle landing gear configuration, 5 holes on either side of the forward center section bulkhead need to be double-flush. Interestingly, I couldn’t find that much information for other builders logs on this step. It seems some people need to the double flush rivets, while other do not.

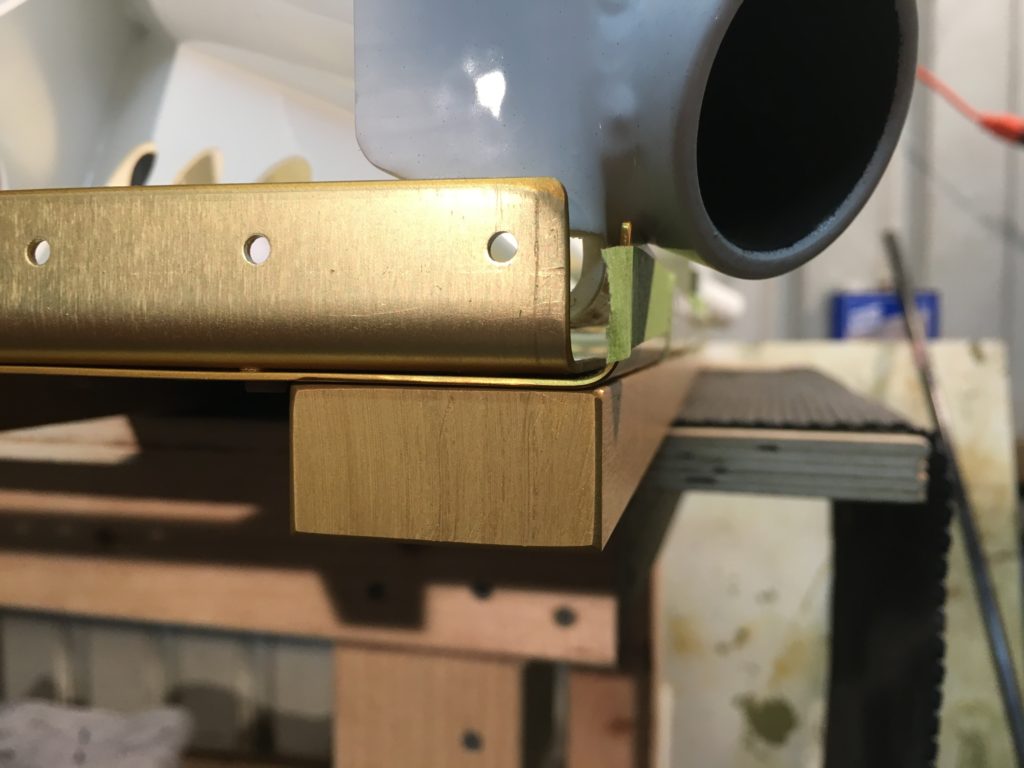

I fit up the main gear weldment against the center section to determine what’s going on here. The main mounting face of the gear did not sit flush against the center section web.

Here’s the culprit. The main tube is contacting the flange. After doing some online research, I found out you need to scallop this area to allow the main flange to sit flat.

Based on the gap between the gear weldment and the flange, it appears to me I don’t need to double flush the rivets. Just to be on the safe side, I decided to partially countersink the inside face of the flange.

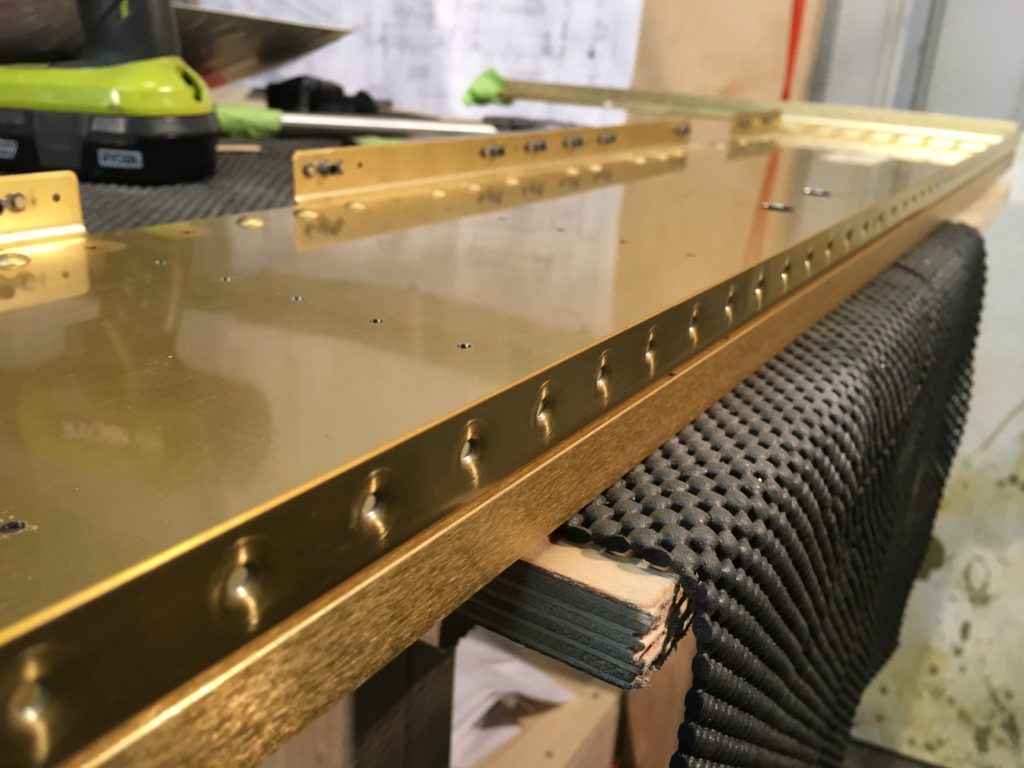

I dimpled the remaining holes on the center section. Van’s gives you the option of dimpling or countersinking these holes. There’s no reason to countersink the holes. A dimple is a much stronger joint compared to a countersunk sheetmetal hole.

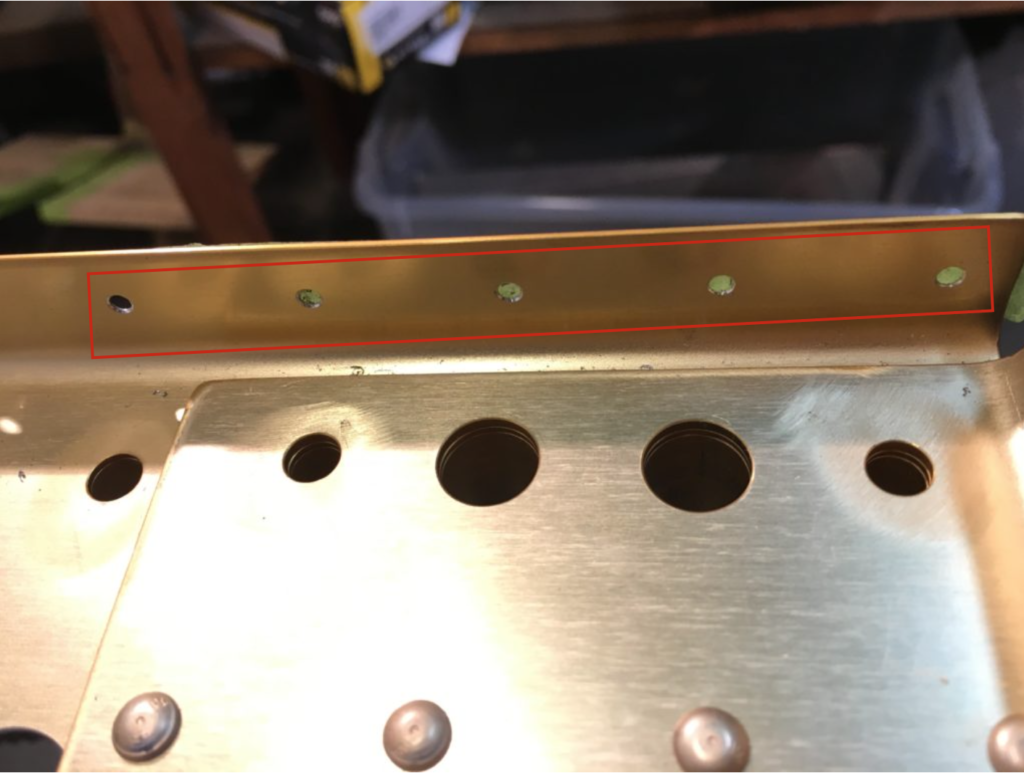

I reached out to the support line at Van’s to determine whether I should be concerned about the edge distance on the F-605C doublers. The plans call for an edge distance of .25 inches. As you can see in the image, I’m around .17 inches. As expected, they said replace the parts. I drilled out the rivets and placed an order for 2 new doublers.