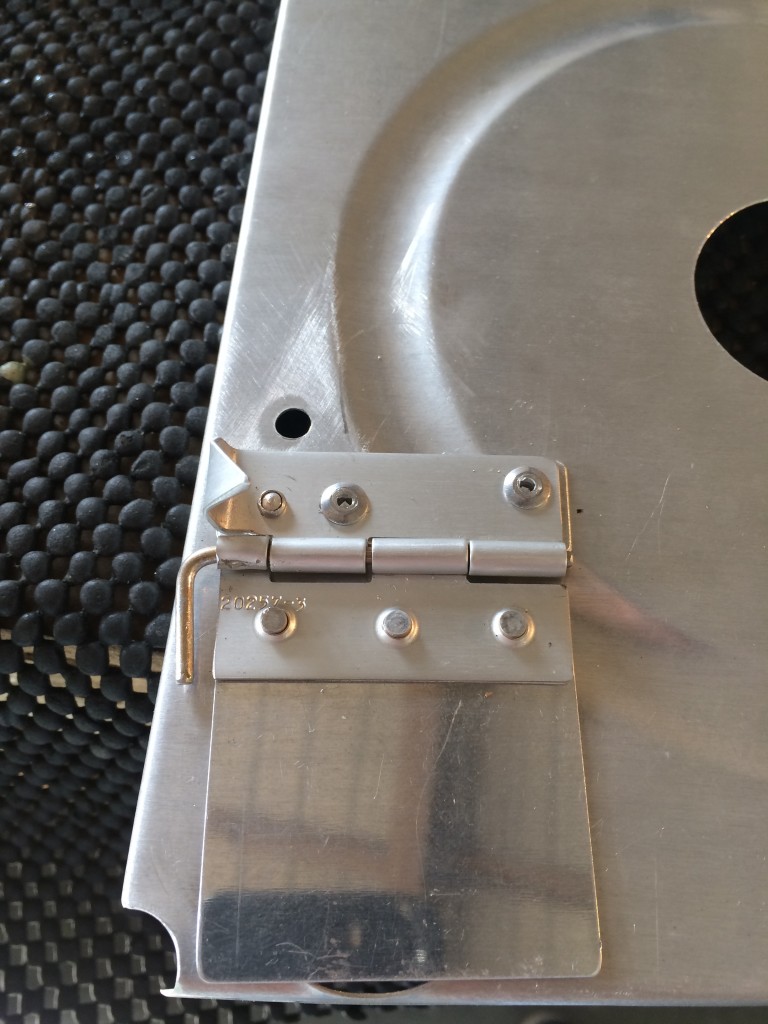

Happy 2016! The first thing I did today was rework the trap door hinge. The bend radius I applied to the tab was much greater to avoid the cracks I saw last time I tried this.

I riveted the hinge to the door with flathead rivets. I just used blind rivets to secure the door to the rib. Vans does not go into specifics regarding the assembly of the hinge, so I checked out a few builder’s logs. To keep the pin in place, I bend a portion of the pin to keep it retained in one direction. After the baffle gets installed, the pin will be retained in the other direction. I also crimped a portion of the hinge to keep the pin clamped in place. I added a small backing place between the hinge and the rib–this allows the door to lay flat against the rib.

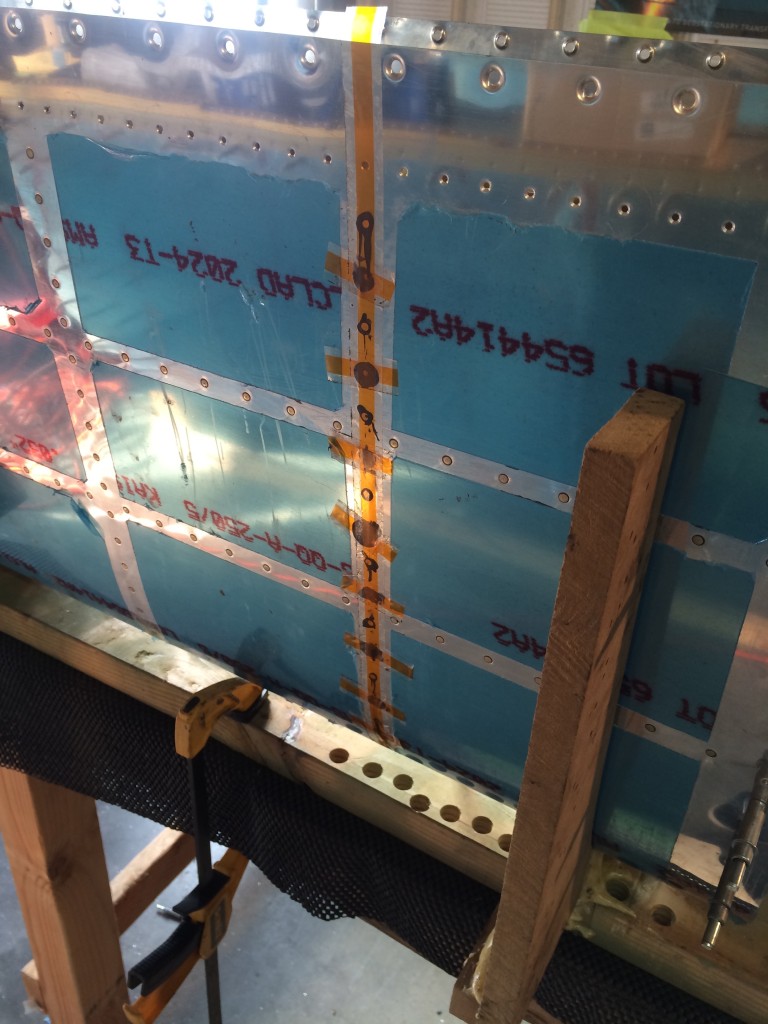

With the trap door behind me, I installed that rib in the tank. No rivets had to be drilled out.

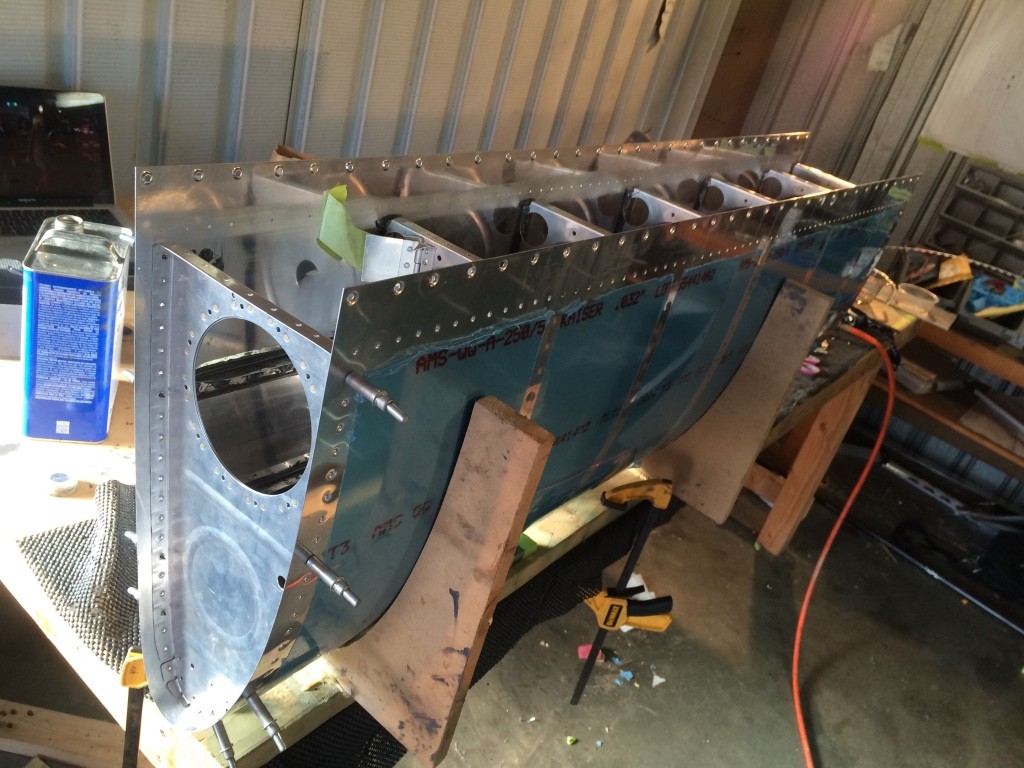

I love seeing the clecos being replaced by rivets. Just one rib to go!

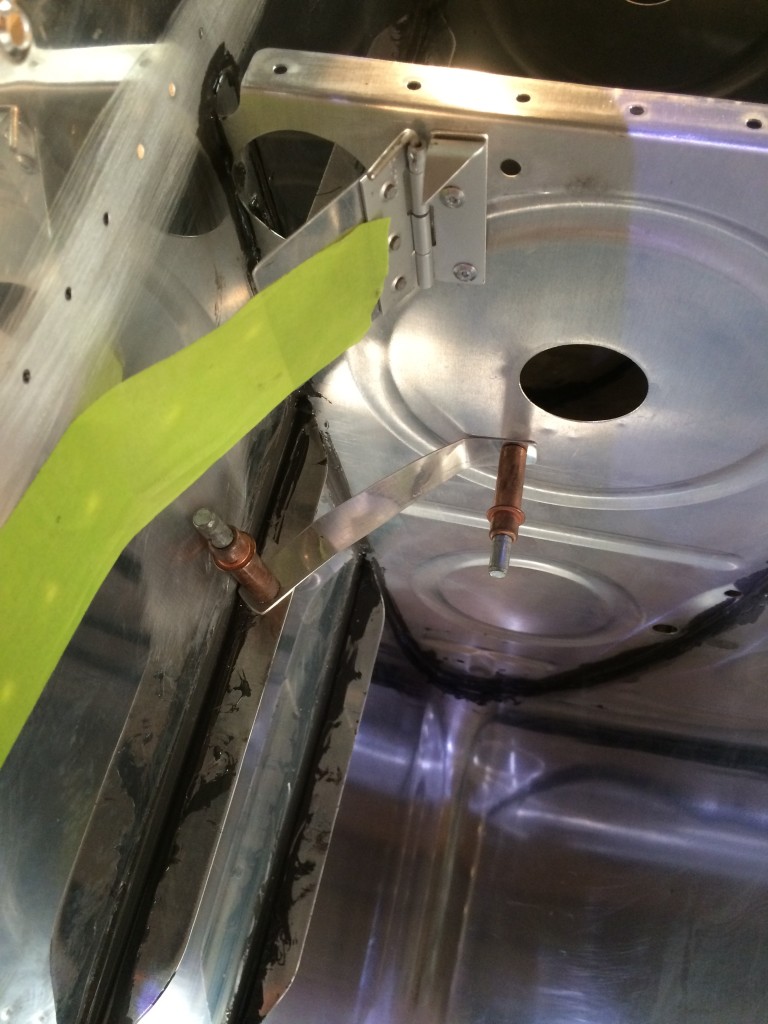

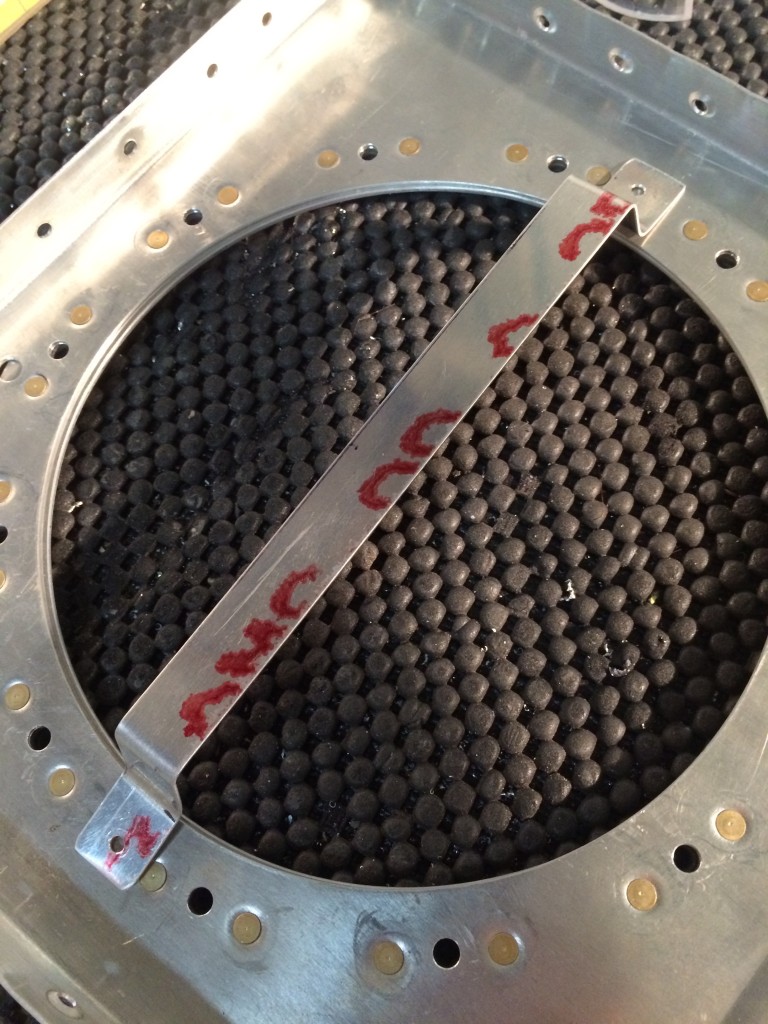

I got the anti-hangup member fabricated. I’m not going to actually install them until the rib is totally sealed. I still need to seal each rivet head. I’m holding the trap door with tape so it does not interfere with the Pro-Seal. The last thing I would want is the door to seal shut!

Here’s the inboard anti-hangup member. It’s actually supposed to be installed on the other side of the rib. I’m not quite sure how to get this installed on the rib. I’m going to do some research later.

The last thing I did was add the 9/16 hole for the fuel port. I’m really upset by the way this turned out. Everything was looking good when I was using the unibit to step up to the final diameter. I used a 9/16 bit to drill to the final size, but I got a ton of chatter, resulting in a really sloppy hole. I should have just stopped when I realized this was not working, but I though the bit would eventually center itself. I’m going to sleep on this issue and think about it later. There’s two lessons here: 1.) If something is not going right, stop immediately. 2.) For any larger hole sizes, use a unibit or hole cutter.