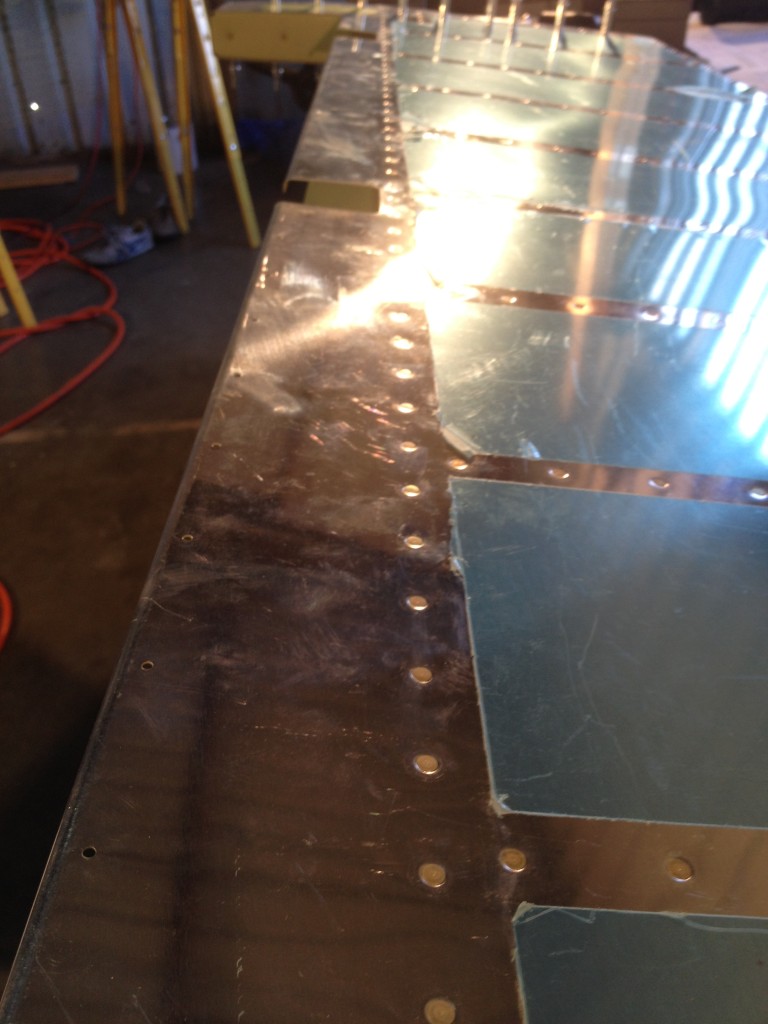

I used the squeezer the set the rivets along the leading edge of the rudder.

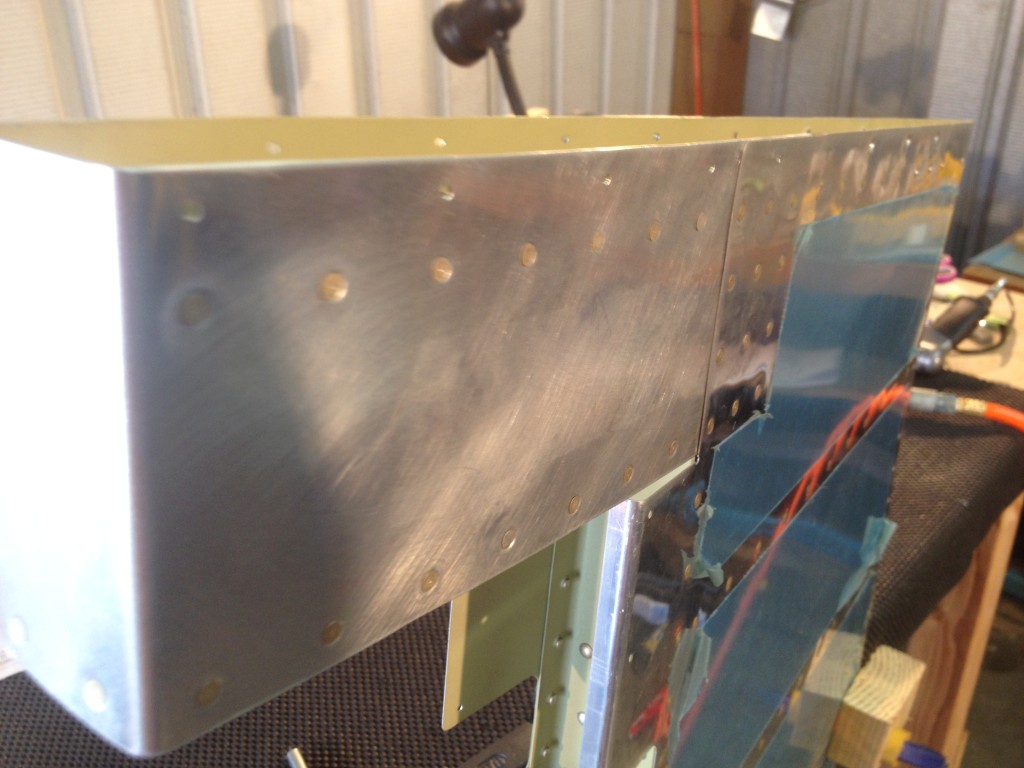

Three blind rivets were used on each side of the trailing edge.

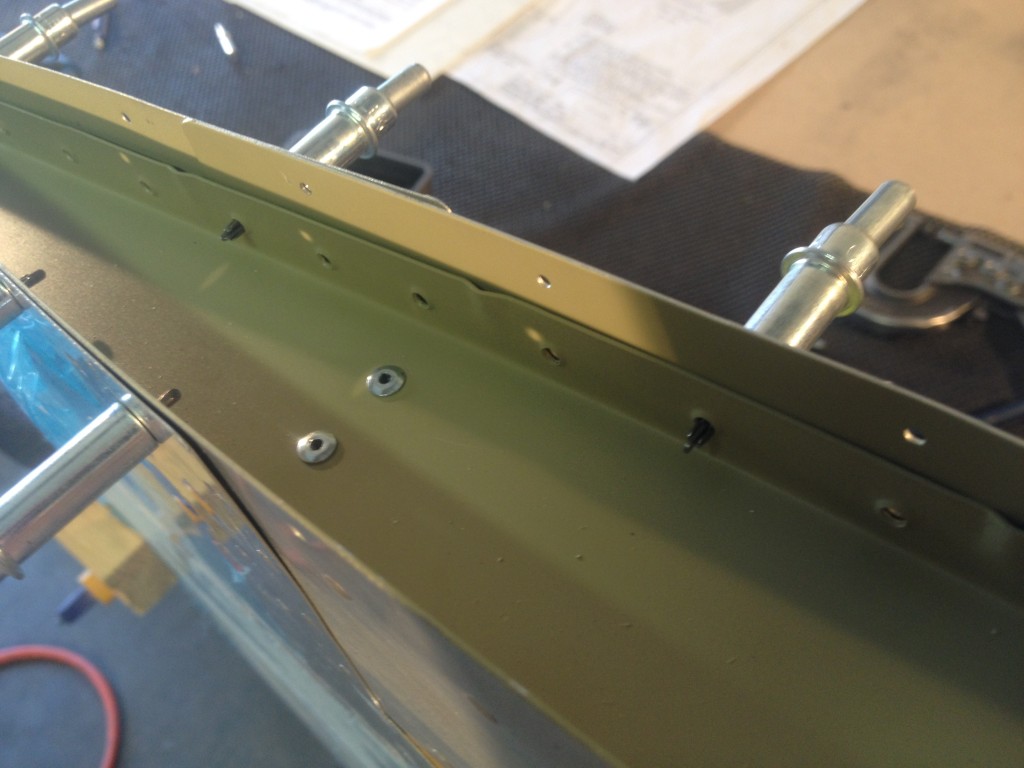

Counterweight installed

I borrowed a Snap-On torque wrench from SpaceX.

I torqued each nut to 27.5 in-lbs.

The plans call out 20-25 in-lbs for 10-32 bolts. I couldn’t figure out what torque caused the nylok nut to rotate. The minimum my torque wrench would measure is 10 in-lbs. I assumed 5 in-lbs causes the nut to rotate.

Therefore, 22.5+5 = 27.5 in-lbs

Used blind rivets to fasten the top rib to the spar.

Riveting completed on the top skin and counterbalance. Three of the rivets were not setting properly. I tried to drill them out, but I opened up the hole too much. I will need to buy Oops Rivets for this issue.

The rudder is starting to look really awesome! Next up is the trailing edge.