Today I focused on getting most of the center fuselage parts prepped for assembly.

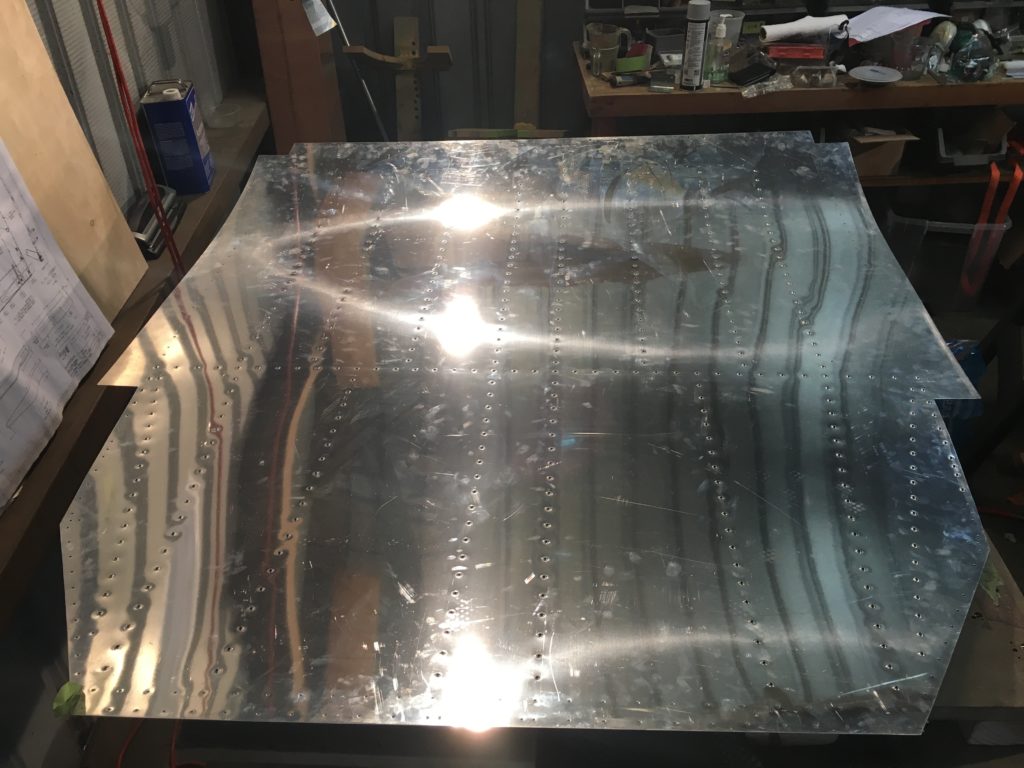

The first thing I did was finish dimpling/deburring the bottom skin. I’m glad all those holes are behind me.

I busted out the dimpling on the F-XXX pieces.

Each seat rib is attached to the F-704 bulkhead with several rivets and screws at the top and bottom of the flange. To locate the screw holes, I used the bulkhead to cut a small point in the flange while the ribs/bulkhead were cleccoed together. The small divot was drilled to the appropriate size after the parts were disassembled.

I cut a scallop in the flanges where wires will pass through the bulkheads. The cutting was accomplished using my grinding wheel and sandpaper.

The last major thing I did was countersink the nut plate rivet holes. Due to the thin material, I’m using Oops rivets in these locations. The hole closest to the edge had to be cut without the countersink cage due to the proximity to the next flange.