The days I’m able to get a solid work session in are pretty infrequent. I’m usually spending about 2 hours on the project during any typical day, which really isn’t enough when I’m only working on the plane 2-3 times per week (or less). Fortunately, I was at the hangar for about 6 hours today and I was able to get a major portion of the roll bar completed.

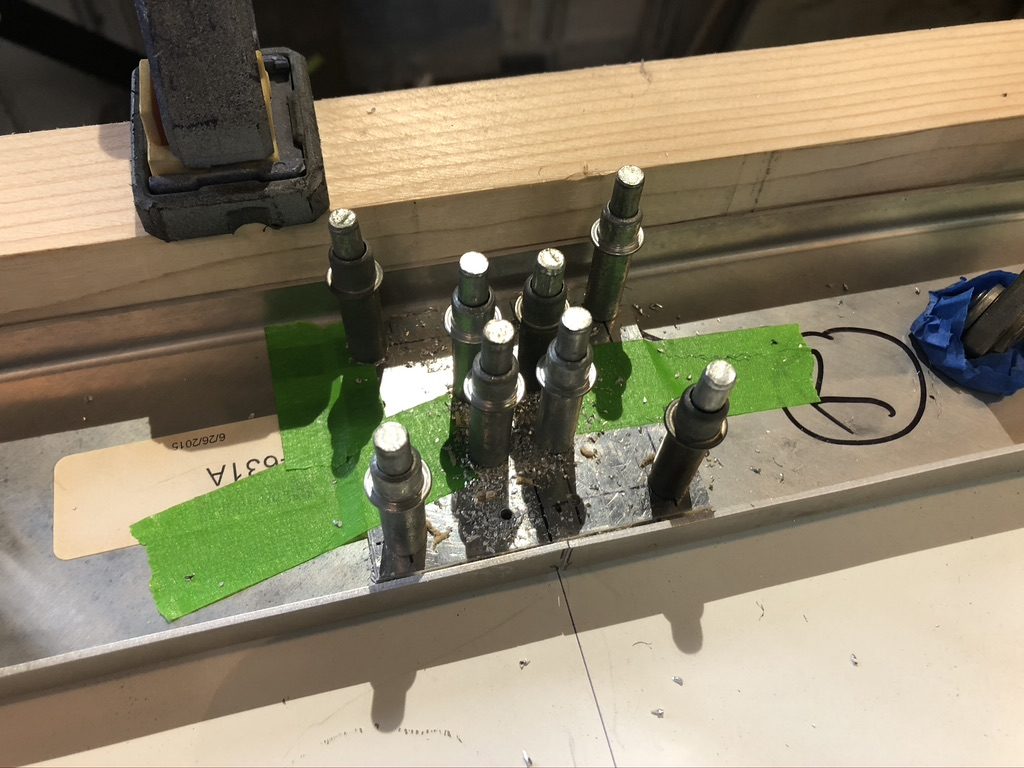

The first thing I did today was match drill the F-631E plate to the aft frame. The clecos were installed directly into the table to hold the center of the frame.

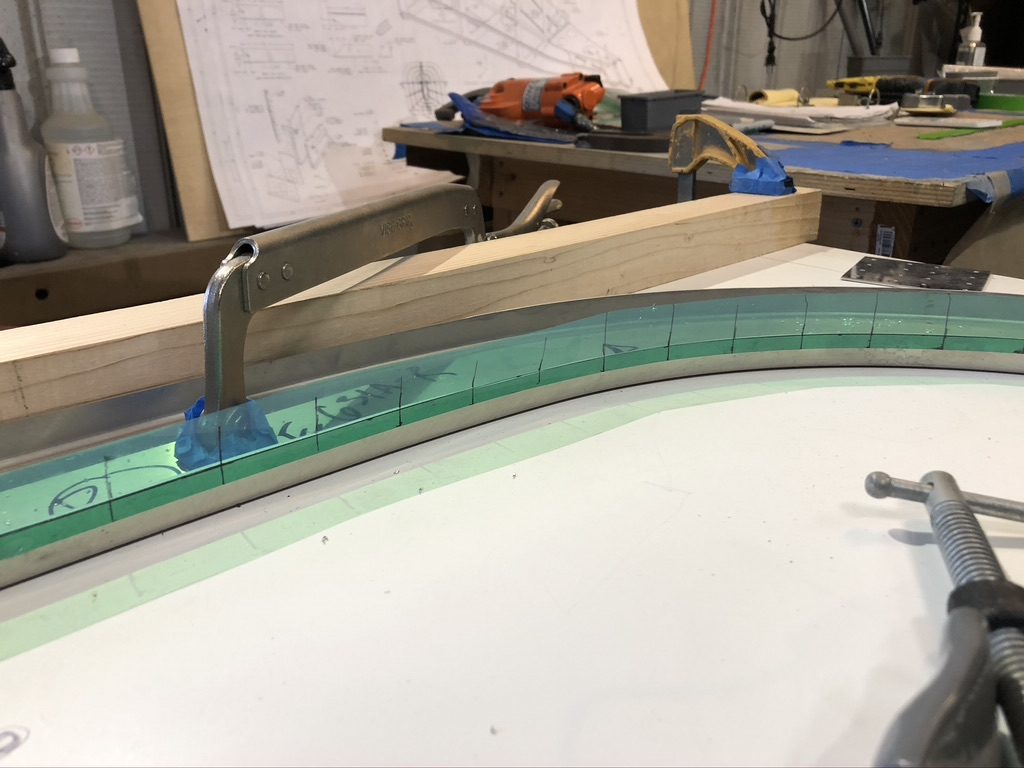

I chamfered the outer edges of the connecting straps. This will enable the straps to sit within the bend of the frame. The pen marks on the strap show the expected gap between the forward and aft frame.

Van’s tells you to space the rivets out 1.5 inches max. I decided to go with 1.25 inch spacing. To translate the hole pattern to the frame, I marked up the hole locations on flash breaker tape before applying the tape to the frame. This method worked really well. I used an extended drill bit to drill the frame before the straps were clamped in place.

Locating the straps was the most time consuming part of the day. It took a solid amount of adjusting and reclamping to get everything to align properly.

You can see all the holes drilled on the inner strap. The outer strap was clamped into place. The outer strap was a bit easier, but it still took awhile to get everything aligned.

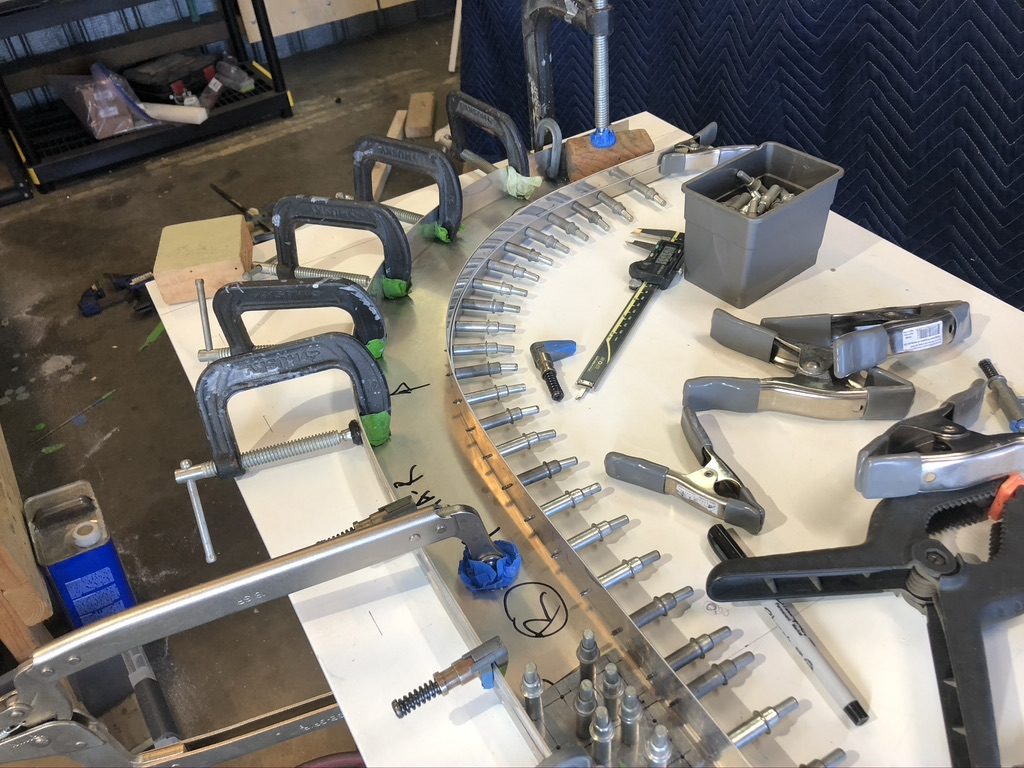

Here’s the product of a solid day at the hangar! This thing looks pretty cool with all the clecos.