Work on the canopy frame continues.

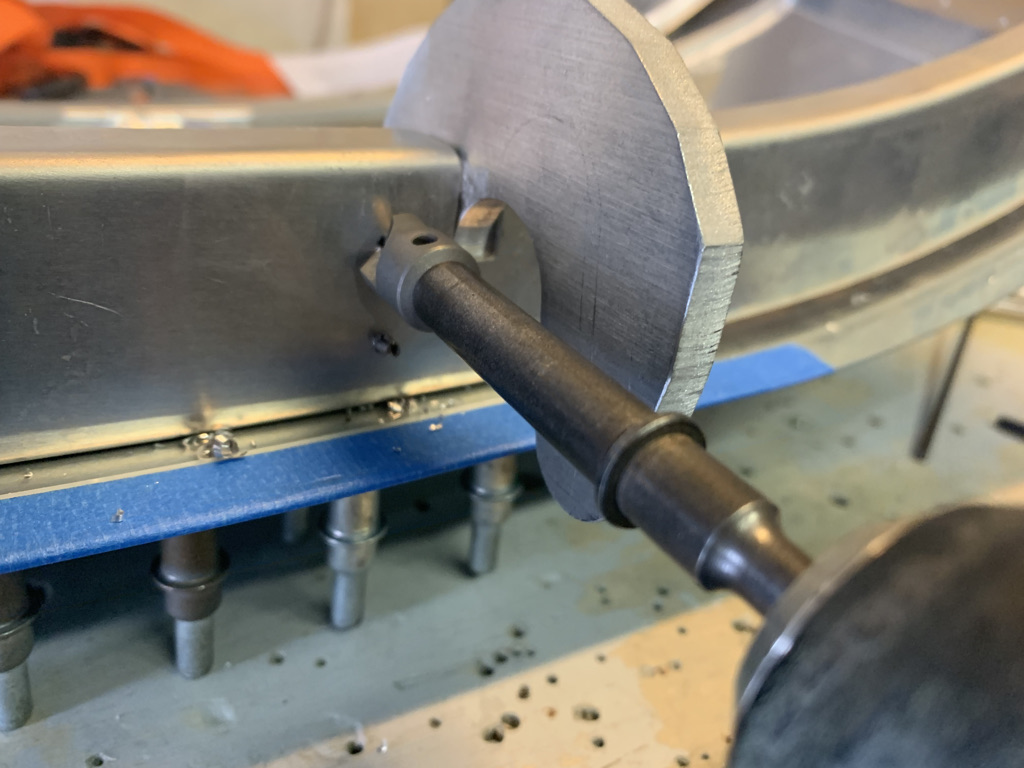

I wanted to double check the hinge pivot location before doing any drilling/riveting on this assembly. I used a Sharpie to mark the location of the hole. I had to pull the frame off the fuselage to check the location. It actually looks pretty good.

To mark the hole, I had to create a one-time use stubby marker to actually be able to get the marker to fit in the forward fuselage area.

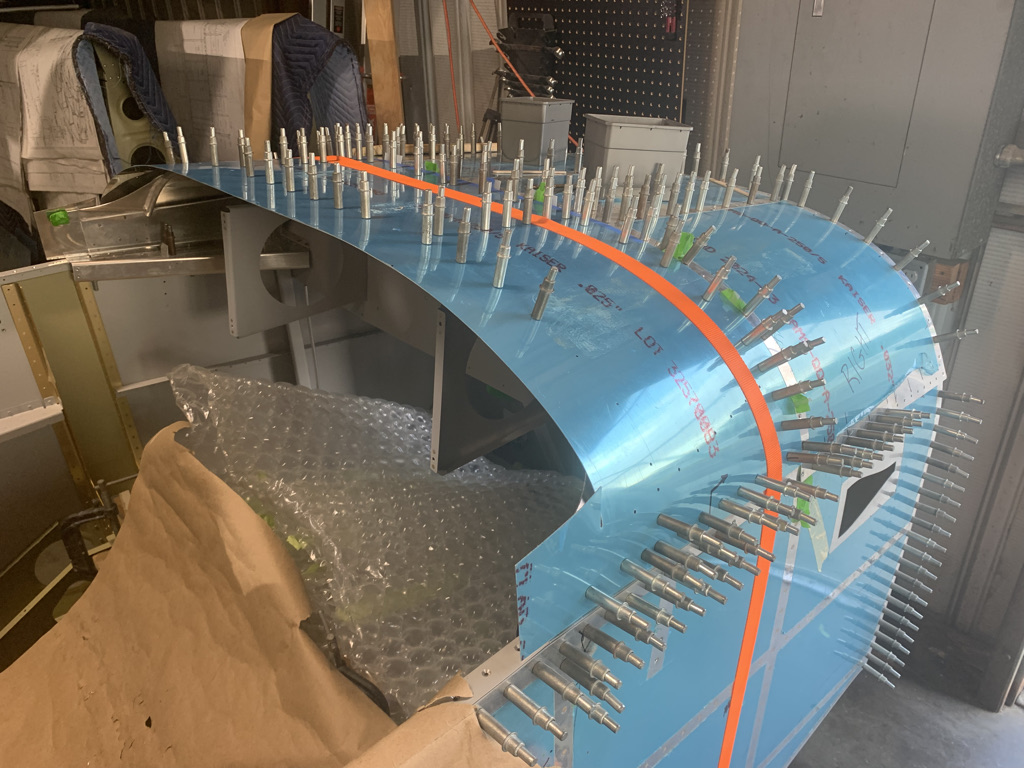

Now that the fit on the canopy frame is looking good, it’s time to get the frame riveted together. The holes on the channel need to be countersunk. The holes on the C-614 Canopy Splice Plate were countersunk without issue. The holes that have to be countersunk around the hinges had to be done without a countersink cage due to the proximity to the hinge. This was an iterative process of slowly removing material and double checking the fit with a rivet.

Since I need to get the frame parts riveted together, I primed the faying surfaces.

The last thing I did was rivet the frame together. I had to use my Main Squeeze to get the rivets around the hinge.