It’s time to rivet the rudder trailing edge. To get started, I removed the clecos that were holding the angle aluminum to the rudder. After that, I spent a ~2 hours cleaning the excess adhesive off the surface of the rudder and all the countersinks.

I bought this special squeezer set from Cleveland Aircraft Tool. It’s supposed to make riveting of the trailing edge easier compared to the back rivet method. Honestly, I think the squeezer set performed average. The issue is that it would leave a shallow indentations on the rudder skin after squeezing. Basically the trailing edge would get squeezer out slightly, which left a superficial mark on the skin. It’s not terrible, but I was hoping this was going to be a little cleaner.

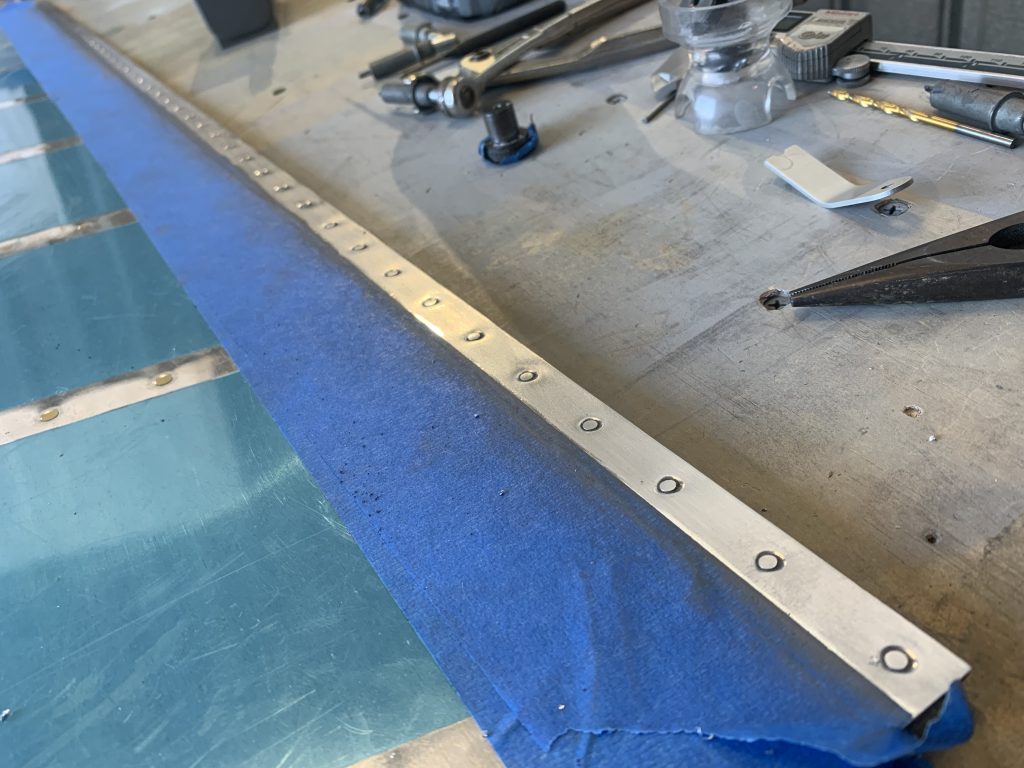

I started the riveting by squeezing every 10th rivet. To start, the rivets were only partially set. After riveting every 5th rivet, I filled in all the gaps with more rivets. After all rivets were partially installed, I squeezed every rivet a bit more until the shop head was flush with the skin.

I abraded the trailing edge of the rudder to clean up the marks from the squeezer. After the trailing edge gets polished, I doubt anyone will be able to tell there was minor superficial damage.