I finally got around the leak checking the right fuel tank. I decided to use the manometer method because I think it’s a little more precise than the balloon method.

After rigging up the manometer, I poured water into the open end of the tube. I expected the water level to rise only on one side of the manometer, which would indicate air pressure was being applied to the inside of the tank. Unfortunately, the water level equalized on both sides on the tube, which means the air in the tank is venting. I have a leak in my tank!

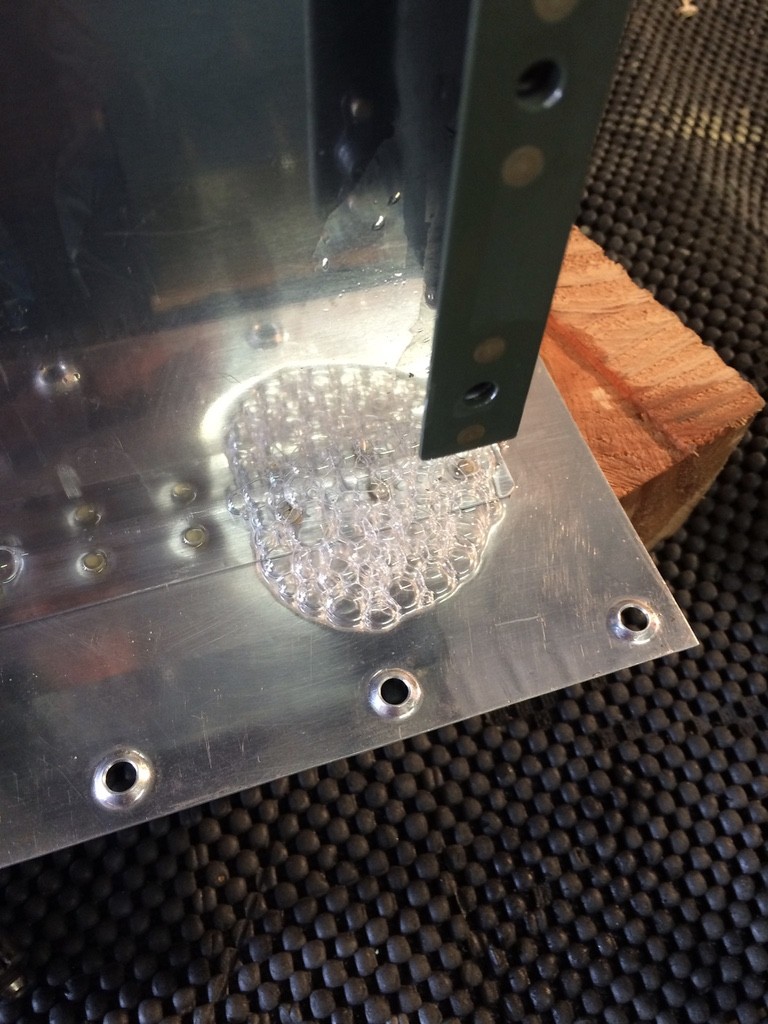

I applied in internal pressure to the tank just by blowing into the tube with my mouth. While applying air pressure, I sprayed the entire tank with Snoop to try to find the leaky interface. It turns out I have two leaks. The interface between the baffle and the skin leaks in two separate locations. The good news is I should be able to just apply a fillet of adhesive to this interface to seal up the leak. If the leak had been on the outer surface of the tank, the problem would have been much more severe.

Since I don’t have time to make a batch of adhesive today, I just deburred and dimpled most of the holes on the left wing skin. This work is pretty mindless, but it needs to get done.