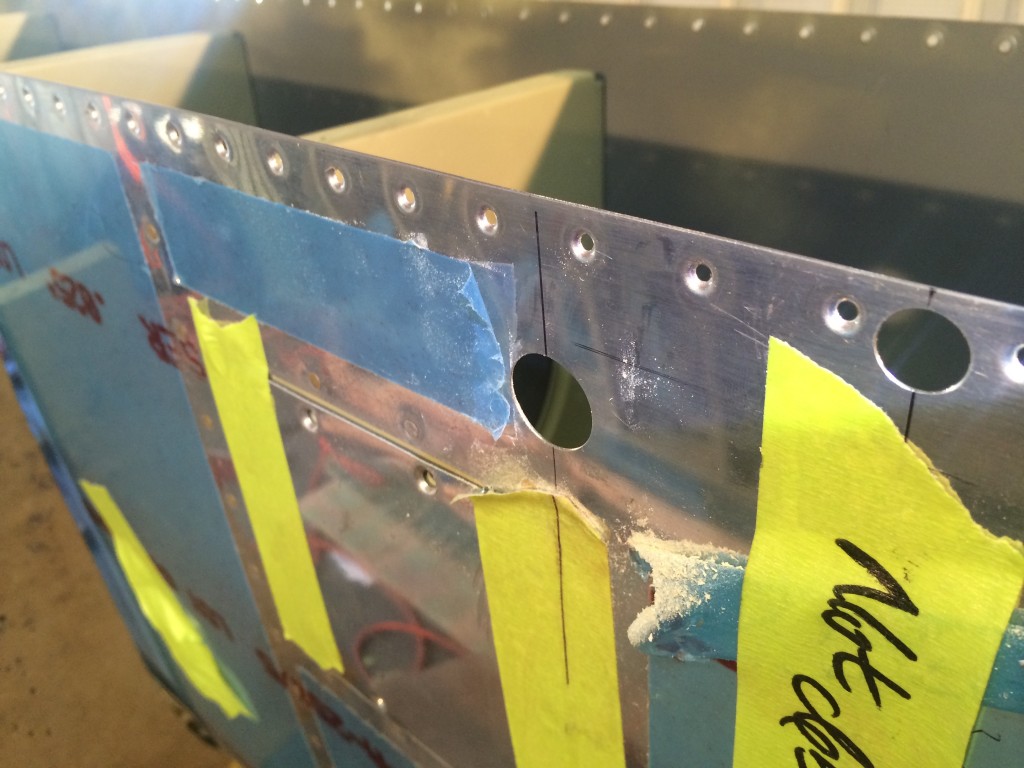

When I drilled the mounting holes for the fuel level sensor, I accidentally used the right sensor has a guide, instead of the left sensor. I didn’t realize the patters were reversed on the sensors.

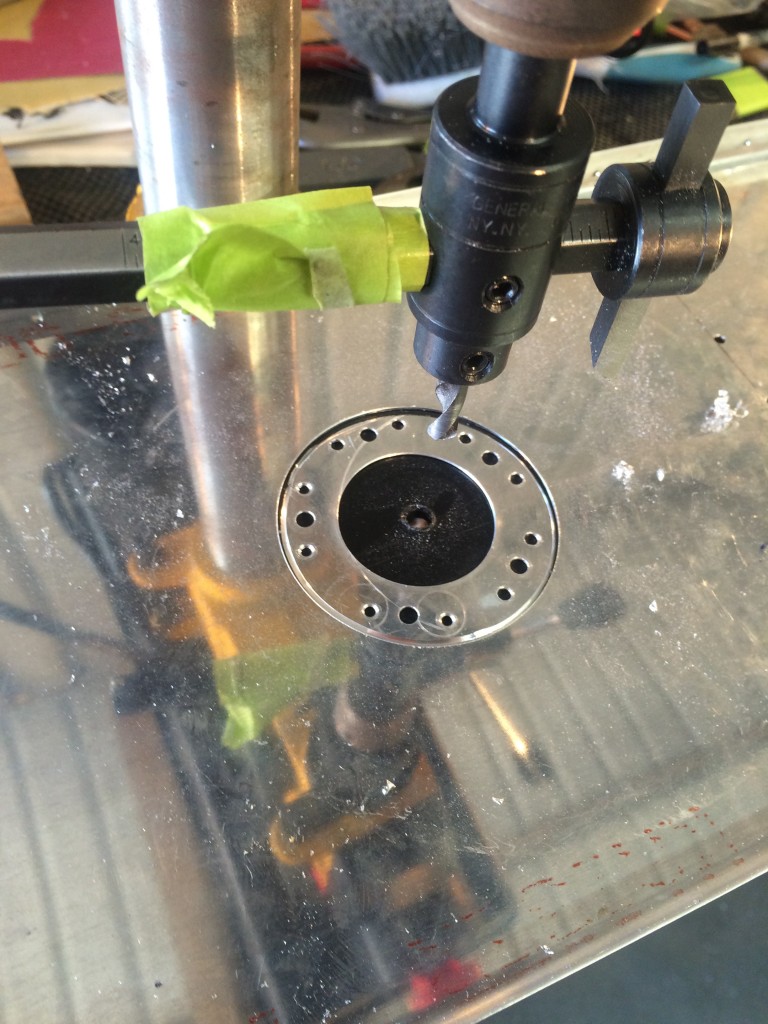

To fix the problem, I used my hole cutter to remove the mis-drilled material.

I fabricated a doubler plate with the correct hole pattern.

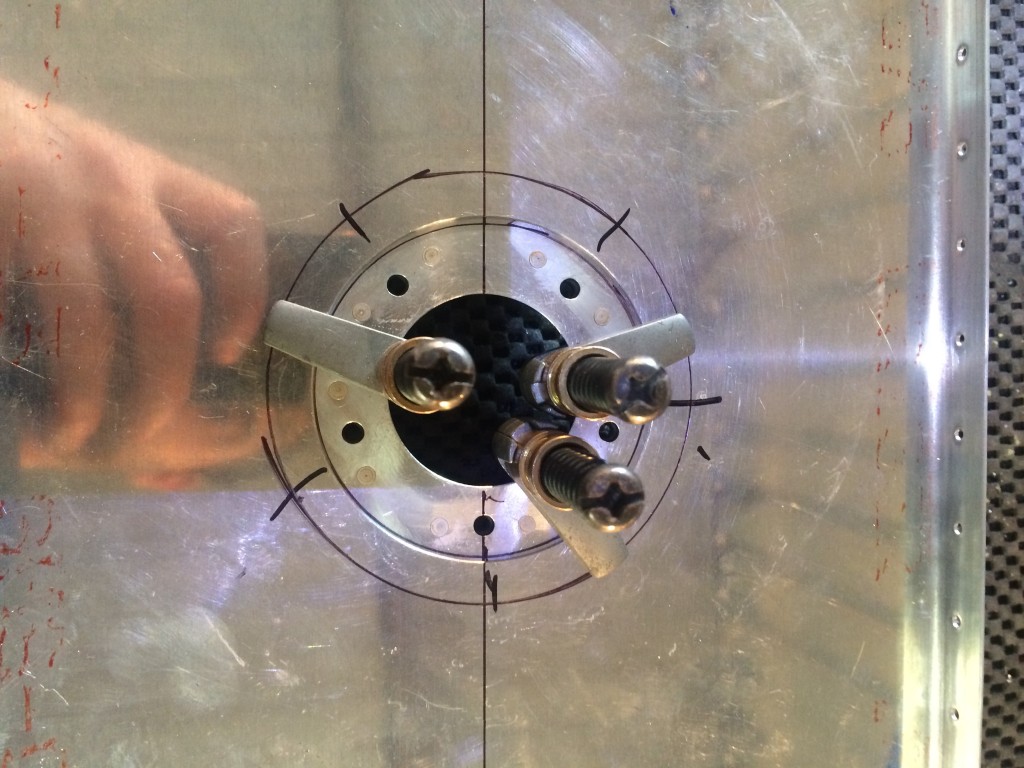

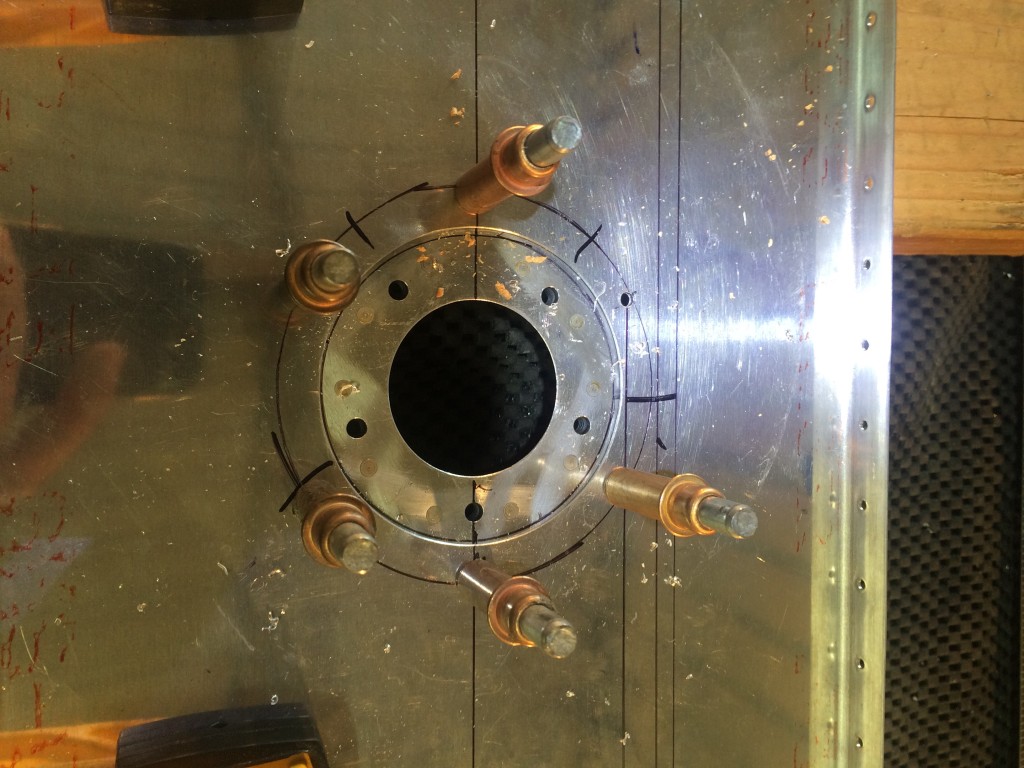

The nut plates were back riveted to the doubler plate.

Finally, I match drilled the doubler plate in the hole location that had been previously cut out.

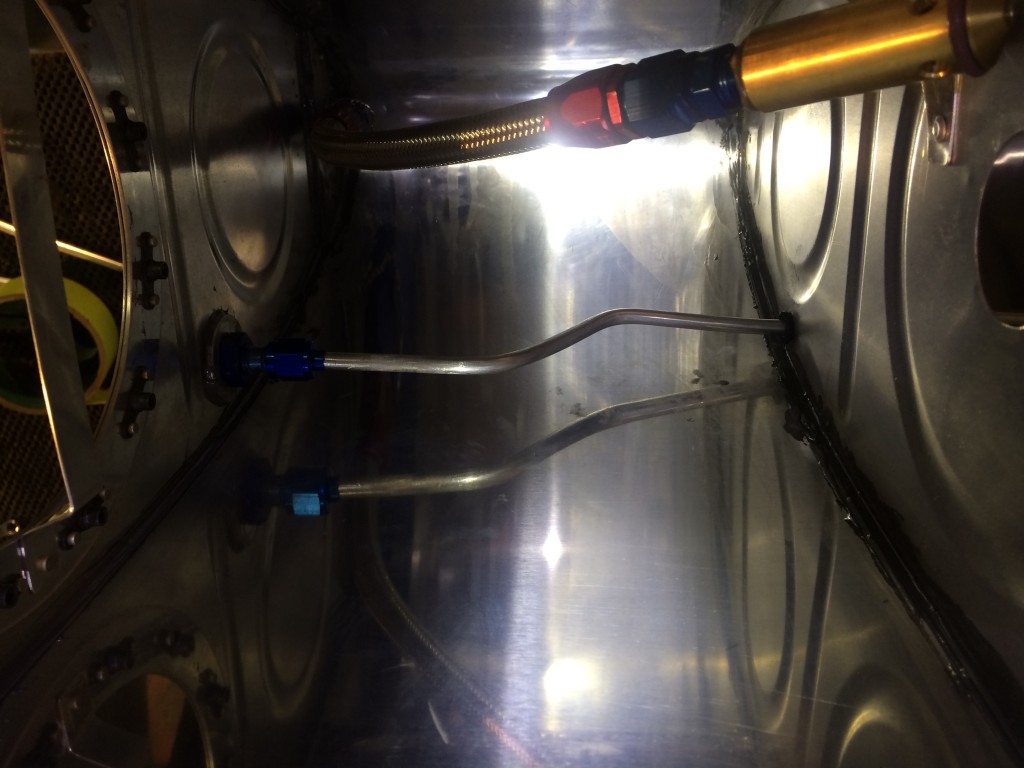

I fabricated the vent tube for the left tank.

The vent tube installation came out really well.

I installed that large rivet to plug the tooling hole.

The last thing I did was open up the hole for the tie down spacer. I used a unibit to get the job done.